Page 234 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 234

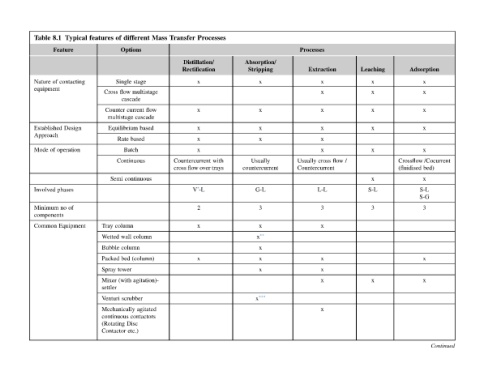

Adsorption x x x x x Crossflow /Cocurrent bed) (fluidised x S-L S-G 3 x x Continued

Leaching x x x x x x S-L 3 x

/

flow

Processes Extraction x x x x x x cross Usually Countercurrent L-L 3 x x x x x

Absorption/ Stripping x x x x Usually countercurrent G-L 3 x x x x x x

Processes Distillation/ Rectification x x x x x with cross flow over trays V -L 2 x x

Transfer Countercurrent

Mass flow

different Options stage multistage cascade current cascade based based Batch Continuous continuous column column (column) agitation)- scrubber agitated contactors Disc etc.)

of Single flow Cross Counter multistage Equilibrium Rate Semi column wall Wetted Bubble bed Packed tower (with Venturi Mechanically continuous (Rotating Contactor

features Tray Spray Mixer settler

Typical contacting Design operation of Equipment

8.1 Feature of of phases no

Table Nature equipment Established Approach Mode Involved Minimum components Common