Page 33 - Process simulation and control using Aspen

P. 33

26 PROCESS SIMULATION AND CONTROL USING ASPEN

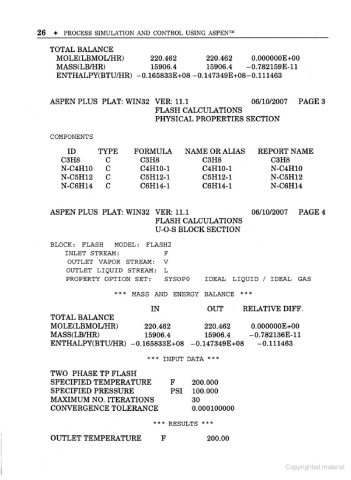

TOTAL BALANCE

MOLE( LBMOL/HR) 220.462 220.462 0.000000E+00

MASS(LB/HR) 15906.4 15906.4 -0.782159E-11

ENTHALPY(BTU/HR) -0.165833E+08 -0.147349E+08-0.111463

ASPEN PLUS PLAT: WIN32 VER: 11.1 06/10/2007 PAGE 3

FLASH CALCULATIONS

PHYSICAL PROPERTIES SECTION

COMPONENTS

ID TYPE FORMULA NAME OR ALIAS REPORT NAME

C3H8 C C3H8 C3H8 C3H8

N-C4H10 C C4H10-1 C4H10-1 N-C4H10

N-C5H12 C C5H12-1 C5H12-1 N-C5H12

N-C6H14 C C6H14-1 C6H14-1 N-C6H14

ASPEN PLUS PLAT: WIN32 VER: 11.1 06/10/2007 PAGE 4

FLASH CALCULATIONS

U-O-S BLOCK SECTION

BLOCK: FLASH MODEL: FLASH2

INLET STREAM: F

OUTLET VAPOR STREAM: V

OUTLET LIQUID STREAM: L

PROPERTY OPTION SET: SYSOP0 IDEAL LIQUID / IDEAL GAS

***

MASS AND ENERGY BALANCE ***

IN OUT RELATIVE DIFF.

TOTAL BALANCE

MOLE(LBMOL/HR) 220.462 220.462 0 000000E+00

.

MASS(LB/HR) 15906.4 15906.4 -0 . 782136E-11

ENTHALPY(BTU/HR) -0.165833E+08 -0.147349E+08 -0.111463

INPUT DATA

TWO PHASE TP FLASH

SPECIFIED TEMPERATURE F 200.000

SPECIFIED PRESSURE PSI 100.000

MAXIMUM NO. ITERATIONS 30

CONVERGENCE TOLERANCE 0 000100000

.

*** RESULTS ***

OUTLET TEMPERATURE F 200.00