Page 129 - Reciprocating Compressors Operation Maintenance

P. 129

116 Reciprocating Compressors: Operation and Maintenance

DISCHARGE o

CHECK VALVE

PRESSURIZED

SUPPLY ADJUSTMENT

-RESERVOIR

riSlirap^

PISTON

wmm it

c^or,,,^-— -TMC-I^ u ROCKER ARM

SPRING-^ Ifeiytf*——ASSEMBLY

CAM

Pumps WHh Pressurized Supplies

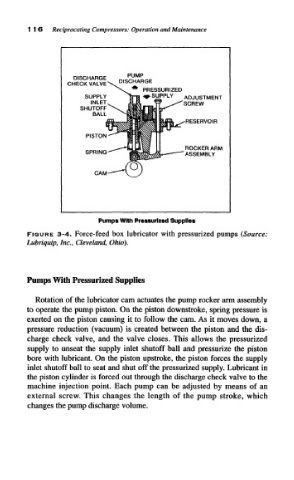

FIGURE 3-4. Force-feed box lubricator with pressurized pumps (Source:

Lubriquip, Inc., Cleveland, Ohio).

Pumps With Pressurized Supplies

Rotation of the lubricator cam actuates the pump rocker arm assembly

to operate the pump piston. On the piston downstroke, spring pressure is

exerted on the piston causing it to follow the cam. As it moves down, a

pressure reduction (vacuum) is created between the piston and the dis-

charge check valve, and the valve closes. This allows the pressurized

supply to unseat the supply inlet shutoff ball and pressurize the piston

bore with lubricant. On the piston upstroke, the piston forces the supply

inlet shutoff ball to seat and shut off the pressurized supply. Lubricant in

the piston cylinder is forced out through the discharge check valve to the

machine injection point. Each pump can be adjusted by means of an

external screw. This changes the length of the pump stroke, which

changes the pump discharge volume.