Page 201 - Reciprocating Compressors Operation Maintenance

P. 201

Operation and Maintenance of Reciprocating Compressors I 87

FATIGUE BREAK POSSIBILITIES

FROM INSIDE

OVERSIZE ROD UNDERSIZE ROD

FIGURE 3-46. Packing ring breaks caused by oversized and undersized pis-

ton rods.

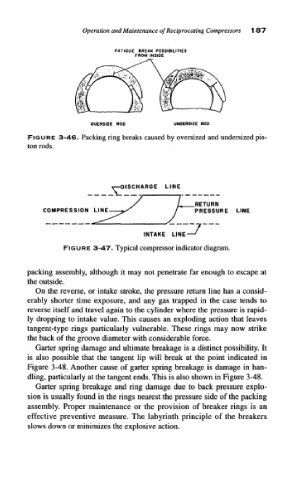

,—DISCHARGE LINE

COMPRESSION LINE

INTAKE LINE

FIGURE 3-47. Typical compressor indicator diagram.

packing assembly, although it may not penetrate far enough to escape at

the outside.

On the reverse, or intake stroke, the pressure return line has a consid-

erably shorter time exposure, and any gas trapped in the case tends to

reverse itself and travel again to the cylinder where the pressure is rapid-

ly dropping to intake value. This causes an exploding action that leaves

tangent-type rings particularly vulnerable. These rings may now strike

the back of the groove diameter with considerable force.

Garter spring damage and ultimate breakage is a distinct possibility. It

is also possible that the tangent lip will break at the point indicated in

Figure 3-48. Another cause of garter spring breakage is damage in han-

dling, particularly at the tangent ends. This is also shown in Figure 3-48.

Garter spring breakage and ring damage due to back pressure explo-

sion is usually found in the rings nearest the pressure side of the packing

assembly. Proper maintenance or the provision of breaker rings is an

effective preventive measure. The labyrinth principle of the breakers

slows down or minimizes the explosive action.