Page 266 - Reciprocating Compressors Operation Maintenance

P. 266

Overhaul and Repair of Reciprocating Compressors 251

Anchor Bolt Hole Clearance

6088 of *.»•.', xvJbft \~\ ^ Crush Provided

Machine f^f-f> m , ^ by Polyurethane

I II I ^B \ Sleeve to Seal

Grout Pour N$M ^ | W \ void Provided by

8-12" Core ^^ • il \ Clearance of

8-12 oore HC4 ^ im \ Anchor Bolt Hole

ch

s

Closed-Cell ll • fW \ K®l . ?®? tion

Polyurethane-

Sleeve

2nd Epoxy

Grout Pour

Threaded

Coupling

1st Epoxy Grout

Pour

Lower Anchor Bolt fEjfi H jlj \ Anchor Section of

s ud

' ^ • Hi /the Anchor Bolt

Anchor Plate and

Upper and Lower

Nuts

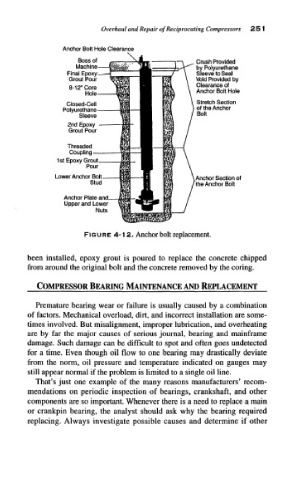

FIGURE 4-12. Anchor bolt replacement.

been installed, epoxy grout is poured to replace the concrete chipped

from around the original bolt and the concrete removed by the coring.

COMPRESSOR BEARING MAINTENANCE AND REPLACEMENT

Premature bearing wear or failure is usually caused by a combination

of factors. Mechanical overload, dirt, and incorrect installation are some-

times involved. But misalignment, improper lubrication, and overheating

are by far the major causes of serious journal, bearing and mainframe

damage. Such damage can be difficult to spot and often goes undetected

for a time. Even though oil flow to one bearing may drastically deviate

from the norm, oil pressure and temperature indicated on gauges may

still appear normal if the problem is limited to a single oil line.

That's just one example of the many reasons manufacturers' recom-

mendations on periodic inspection of bearings, crankshaft, and other

components are so important. Whenever there is a need to replace a main

or crankpin bearing, the analyst should ask why the bearing required

replacing. Always investigate possible causes and determine if other