Page 27 - Reciprocating Compressors Operation Maintenance

P. 27

1 4 Reciprocating Compressors: Operation and Maintenance

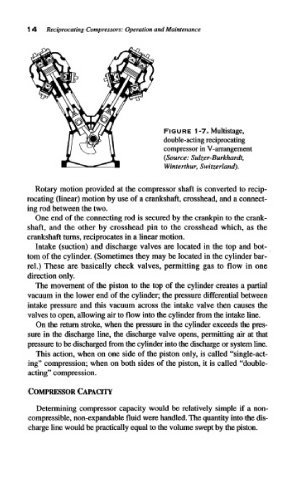

FIGURE 1-7. Multistage,

double-acting reciprocating

compressor in V-arrangement

(Source: Sulzer-Burkhardt,

Winterthur, Switzerland).

Rotary motion provided at the compressor shaft is converted to recip-

rocating (linear) motion by use of a crankshaft, crosshead, and a connect-

ing rod between the two.

One end of the connecting rod is secured by the crankpin to the crank-

shaft, and the other by crosshead pin to the crosshead which, as the

crankshaft turns, reciprocates in a linear motion.

Intake (suction) and discharge valves are located in the top and bot-

tom of the cylinder. (Sometimes they may be located in the cylinder bar-

rel.) These are basically check valves, permitting gas to flow in one

direction only.

The movement of (he piston to the top of the cylinder creates a partial

vacuum in the lower end of the cylinder; the pressure differential between

intake pressure and this vacuum across the intake valve then causes the

valves to open, allowing air to flow into the cylinder from the intake line.

On the return stroke, when the pressure in the cylinder exceeds the pres-

sure in the discharge line, the discharge valve opens, permitting air at that

pressure to be discharged from the cylinder into the discharge or system line.

This action, when on one side of the piston only, is called "single-act-

ing" compression; when on both sides of the piston, it is called "double-

acting" compression.

Determining compressor capacity would be relatively simple if a non-

compressible, non-expandable fluid were handled. The quantity into the dis-

charge line would be practically equal to the volume swept by the piston.