Page 419 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 419

Agroindustry wastes: biofuels and biomaterials feedstocks for sustainable rural development 377

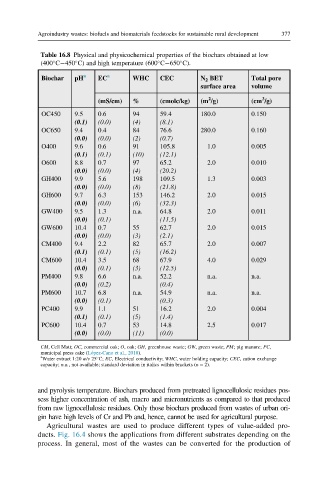

Table 16.8 Physical and physicochemical properties of the biochars obtained at low

(400 C 450 C) and high temperature (600 C 650 C).

Biochar pH a EC a WHC CEC N 2 BET Total pore

surface area volume

2

3

(mS/cm) % (cmolc/kg) (m /g) (cm /g)

OC450 9.5 0.6 94 59.4 180.0 0.150

(0.1) (0.0) (4) (8.1)

OC650 9.4 0.4 84 76.6 280.0 0.160

(0.0) (0.0) (2) (0.7)

O400 9.6 0.6 91 105.8 1.0 0.005

(0.1) (0.1) (10) (12.1)

O600 8.8 0.7 97 65.2 2.0 0.010

(0.0) (0.0) (4) (20.2)

GH400 9.9 5.6 198 109.5 1.3 0.003

(0.0) (0.0) (8) (21.8)

GH600 9.7 6.3 153 146.2 2.0 0.015

(0.0) (0.0) (6) (32.3)

GW400 9.5 1.3 n.a. 64.8 2.0 0.011

(0.0) (0.1) (11.5)

GW600 10.4 0.7 55 62.7 2.0 0.015

(0.0) (0.0) (3) (2.1)

CM400 9.4 2.2 82 65.7 2.0 0.007

(0.1) (0.1) (5) (16.2)

CM600 10.4 3.5 68 67.9 4.0 0.029

(0.0) (0.1) (3) (12.5)

PM400 9.8 6.6 n.a. 52.2 n.a. n.a.

(0.0) (0.2) (0.4)

PM600 10.7 6.8 n.a. 54.9 n.a. n.a.

(0.0) (0.1) (0.3)

PC400 9.9 1.1 51 16.2 2.0 0.004

(0.1) (0.1) (5) (1.4)

PC600 10.4 0.7 53 14.8 2.5 0.017

(0.0) (0.0) (11) (0.0)

CM, Cell Matt; OC, commercial oak; O, oak; GH, greenhouse waste; GW, green waste; PM; pig manure; PC,

municipal press cake (Lo ´pez-Cano et al., 2018).

a

Water extract 1:20 w/v 25 C; EC, Electrical conductivity; WHC, water holding capacity; CEC, cation exchange

capacity; n.a., not available; standard deviation in italics within brackets (n 5 2).

and pyrolysis temperature. Biochars produced from pretreated lignocellulosic residues pos-

sess higher concentration of ash, macro and micronutrients as compared to that produced

from raw lignocellulosic residues. Only those biochars produced from wastes of urban ori-

gin have high levels of Cr and Pb and, hence, cannot be used for agricultural purpose.

Agricultural wastes are used to produce different types of value-added pro-

ducts. Fig. 16.4 shows the applications from different substrates depending on the

process. In general, most of the wastes can be converted for the production of