Page 56 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 56

Bacterial production of fatty acid and biodiesel: opportunity and challenges 33

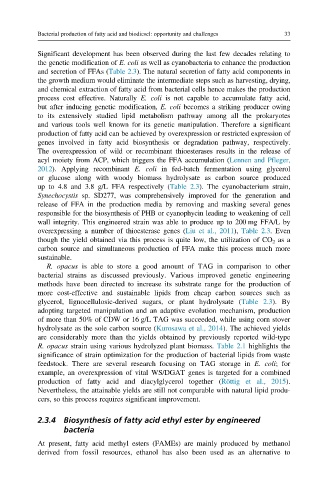

Significant development has been observed during the last few decades relating to

the genetic modification of E. coli as well as cyanobacteria to enhance the production

and secretion of FFAs (Table 2.3). The natural secretion of fatty acid components in

the growth medium would eliminate the intermediate steps such as harvesting, drying,

and chemical extraction of fatty acid from bacterial cells hence makes the production

process cost effective. Naturally E. coli is not capable to accumulate fatty acid,

but after inducing genetic modification, E. coli becomes a striking producer owing

to its extensively studied lipid metabolism pathway among all the prokaryotes

and various tools well known for its genetic manipulation. Therefore a significant

production of fatty acid can be achieved by overexpression or restricted expression of

genes involved in fatty acid biosynthesis or degradation pathway, respectively.

The overexpression of wild or recombinant thioesterases results in the release of

acyl moiety from ACP, which triggers the FFA accumulation (Lennen and Pfleger,

2012). Applying recombinant E. coli in fed-batch fermentation using glycerol

or glucose along with woody biomass hydrolysate as carbon source produced

up to 4.8 and 3.8 g/L FFA respectively (Table 2.3). The cyanobacterium strain,

Synechocystis sp. SD277, was comprehensively improved for the generation and

release of FFA in the production media by removing and masking several genes

responsible for the biosynthesis of PHB or cyanophycin leading to weakening of cell

wall integrity. This engineered strain was able to produce up to 200 mg FFA/L by

overexpressing a number of thioesterase genes (Liu et al., 2011), Table 2.3. Even

though the yield obtained via this process is quite low, the utilization of CO 2 as a

carbon source and simultaneous production of FFA make this process much more

sustainable.

R. opacus is able to store a good amount of TAG in comparison to other

bacterial strains as discussed previously. Various improved genetic engineering

methods have been directed to increase its substrate range for the production of

more cost-effective and sustainable lipids from cheap carbon sources such as

glycerol, lignocellulosic-derived sugars, or plant hydrolysate (Table 2.3). By

adopting targeted manipulation and an adaptive evolution mechanism, production

of more than 50% of CDW or 16 g/L TAG was succeeded, while using corn stover

hydrolysate as the sole carbon source (Kurosawa et al., 2014). The achieved yields

are considerably more than the yields obtained by previously reported wild-type

R. opacus strain using various hydrolyzed plant biomass. Table 2.1 highlights the

significance of strain optimization for the production of bacterial lipids from waste

feedstock. There are several research focusing on TAG storage in E. coli; for

example, an overexpression of vital WS/DGAT genes is targeted for a combined

production of fatty acid and diacylglycerol together (Ro ¨ttig et al., 2015).

Nevertheless, the attainable yields are still not comparable with natural lipid produ-

cers, so this process requires significant improvement.

2.3.4 Biosynthesis of fatty acid ethyl ester by engineered

bacteria

At present, fatty acid methyl esters (FAMEs) are mainly produced by methanol

derived from fossil resources, ethanol has also been used as an alternative to