Page 58 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 58

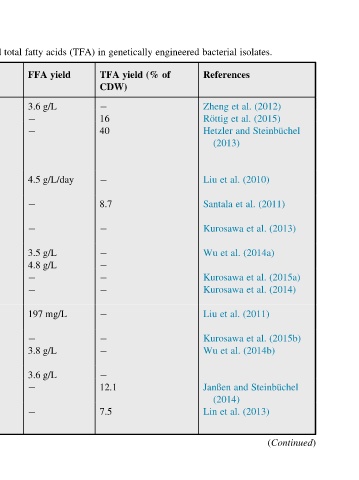

isolates. (2012) al. (2015) al. Steinbuchel ¨ and (2010) (2011) al. et (2013) al. et (2014a) (2015a) al. et (2014) al. et (2011) (2015b) al. et (2014b) Steinbuchel ¨ and (2013) (Continued)

bacterial References et Zheng et Rottig ¨ Hetzler (2013) al. et Liu Santala Kurosawa al. et Wu Kurosawa Kurosawa al. et Liu Kurosawa al. et Wu Janßen (2014) al. et Lin

engineered of

genetically (% yield

in TFA CDW) 16 40 8.7 12.1 7.5

(TFA)

acids yield g/L g/L/day g/L g/L mg/L g/L g/L

fatty FFA 3.6 4.5 3.5 4.8 197 3.8 3.6

total

and of

(FFA), (% yield

acids TAG CDW)

fatty 45.8 46 54 39.7 8.5 4.9

free glucose

(TAG), carbon glucose or medium gluconate and hardwood glycerol and corn of woody of glucose (fed-batch with

triacylglycerol of Source Glycerin Complex Cellobiose Glycerol Glycerol Kraft (hydrolysate) Crude Glycerol acid Acetic Hydrolysate stover CO 2 Arabinose Hydrolysate biomass and Xylose Lactose fermentation) medium LB glucose

of LL18 pXZ18z

Production coli pc::ff:ppt opacus pEC- XL100/ baylyi Xsp8 MLK211 pBADNP MITXM-61 sp. MITAE-348

2.3 Escherichia BL21 Rhodococcus PD630 K18mob2:: bglABC TF BL21 pMSD8/pTL58 Acinetobacter opacus pXZ18z opacus Synechocystis SD277 opacus ML190 MG1655 Δp2AAF BL21 ΔdgkAIWS1

Table Strain coli E. coli E. M4 R. coli E. R. R. coli E. coli E. coli E.