Page 87 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 87

62 Refining Biomass Residues for Sustainable Energy and Bioproducts

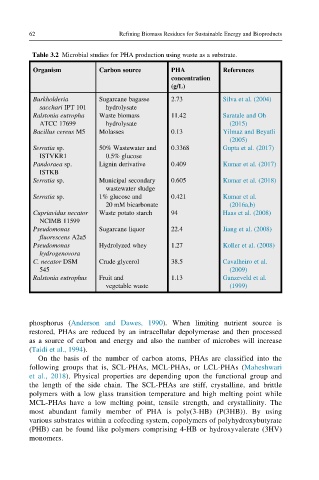

Table 3.2 Microbial studies for PHA production using waste as a substrate.

Organism Carbon source PHA References

concentration

(g/L)

Burkholderia Sugarcane bagasse 2.73 Silva et al. (2004)

sacchari IPT 101 hydrolysate

Ralstonia eutropha Waste biomass 11.42 Saratale and Oh

ATCC 17699 hydrolysate (2015)

Bacillus cereus M5 Molasses 0.13 Yilmaz and Beyatli

(2005)

Serratia sp. 50% Wastewater and 0.3368 Gupta et al. (2017)

ISTVKR1 0.5% glucose

Pandoraea sp. Lignin derivative 0.409 Kumar et al. (2017)

ISTKB

Serratia sp. Municipal secondary 0.605 Kumar et al. (2018)

wastewater sludge

Serratia sp. 1% glucose and 0.421 Kumar et al.

20 mM bicarbonate (2016a,b)

Cupriavidus necator Waste potato starch 94 Haas et al. (2008)

NCIMB 11599

Pseudomonas Sugarcane liquor 22.4 Jiang et al. (2008)

fluorescens A2a5

Pseudomonas Hydrolyzed whey 1.27 Koller et al. (2008)

hydrogenovora

C. necator DSM Crude glycerol 38.5 Cavalheiro et al.

545 (2009)

Ralstonia eutrophus Fruit and 1.13 Ganzeveld et al.

vegetable waste (1999)

phosphorus (Anderson and Dawes, 1990). When limiting nutrient source is

restored, PHAs are reduced by an intracellular depolymerase and then processed

as a source of carbon and energy and also the number of microbes will increase

(Taidi et al., 1994).

On the basis of the number of carbon atoms, PHAs are classified into the

following groups that is, SCL-PHAs, MCL-PHAs, or LCL-PHAs (Maheshwari

et al., 2018). Physical properties are depending upon the functional group and

the length of the side chain. The SCL-PHAs are stiff, crystalline, and brittle

polymers with a low glass transition temperature and high melting point while

MCL-PHAs have a low melting point, tensile strength, and crystallinity. The

most abundant family member of PHA is poly(3-HB) (P(3HB)). By using

various substrates within a cofeeding system, copolymers of polyhydroxybutyrate

(PHB) can be found like polymers comprising 4-HB or hydroxyvalerate (3HV)

monomers.