Page 17 - Reliability and Maintainability of In service Pipelines

P. 17

6 Reliability and Maintainability of In-Service Pipelines

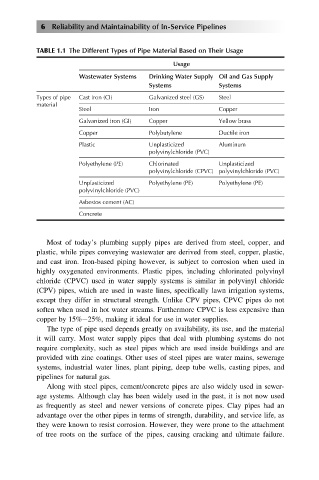

TABLE 1.1 The Different Types of Pipe Material Based on Their Usage

Usage

Wastewater Systems Drinking Water Supply Oil and Gas Supply

Systems Systems

Types of pipe Cast iron (CI) Galvanized steel (GS) Steel

material

Steel Iron Copper

Galvanized iron (GI) Copper Yellow brass

Copper Polybutylene Ductile iron

Plastic Unplasticized Aluminum

polyvinylchloride (PVC)

Polyethylene (PE) Chlorinated Unplasticized

polyvinylchloride (CPVC) polyvinylchloride (PVC)

Unplasticized Polyethylene (PE) Polyethylene (PE)

polyvinylchloride (PVC)

Asbestos cement (AC)

Concrete

Most of today’s plumbing supply pipes are derived from steel, copper, and

plastic, while pipes conveying wastewater are derived from steel, copper, plastic,

and cast iron. Iron-based piping however, is subject to corrosion when used in

highly oxygenated environments. Plastic pipes, including chlorinated polyvinyl

chloride (CPVC) used in water supply systems is similar in polyvinyl chloride

(CPV) pipes, which are used in waste lines, specifically lawn irrigation systems,

except they differ in structural strength. Unlike CPV pipes, CPVC pipes do not

soften when used in hot water streams. Furthermore CPVC is less expensive than

copper by 15% 25%, making it ideal for use in water supplies.

The type of pipe used depends greatly on availability, its use, and the material

it will carry. Most water supply pipes that deal with plumbing systems do not

require complexity, such as steel pipes which are used inside buildings and are

provided with zinc coatings. Other uses of steel pipes are water mains, sewerage

systems, industrial water lines, plant piping, deep tube wells, casting pipes, and

pipelines for natural gas.

Along with steel pipes, cement/concrete pipes are also widely used in sewer-

age systems. Although clay has been widely used in the past, it is not now used

as frequently as steel and newer versions of concrete pipes. Clay pipes had an

advantage over the other pipes in terms of strength, durability, and service life, as

they were known to resist corrosion. However, they were prone to the attachment

of tree roots on the surface of the pipes, causing cracking and ultimate failure.