Page 48 - Reliability and Maintainability of In service Pipelines

P. 48

Introduction 37

1

ion content, pH, conductivity, temperature variations, and humidity. Similarly,

the level of corrosion occurring in ferrous pipes in petrochemical plants would be

very different to ferrous pipes that carry only “mild” corrosive chemicals.

The level of corrosion resulting in failure of these pipes would also depend on

the factors stated above, for example, the failure rate of ductile iron may be dif-

ferent than wrought iron. If the failure rate was conducted only on the basis of

strength, given that wrought iron is pure and therefore may last longer, it may

take longer than ductile iron to fail. However, under various conditions to which

these two types of pipes are subject, such as corrosive environments, failure rates

may be prone to change.

It is known that protective coatings and linings are used in ferrous pipes to

protect them against caustic environments, such as exposure to aggressive soils,

and corrosive agents. Without the presence of these protective layers covering the

surface of these metals, it allows a direct path for corrosion to occur. Also various

1

factors including temperature fluctuations, humidity, ion content, pH, and expo-

sure to corrosive substances can break down the protective coatings and linings.

In water distribution systems, although cast iron pipes are being phased out of

the water pipeline networks in many countries, a significant portion of current

networks are comprised of cast iron pipes with some of them up to 150 years old.

There are approximately 335,000 km of water mains in the United Kingdom and

more than 60% is estimated to be cast iron pipes (Water UK, 2007). In the United

Kingdom, the failure rate of cast iron pipes can be as high as 3000 failures per

year (i.e., 10 bursts/1000 km/year) (UKWIR, 2002). Of many mechanisms for

pipe failures, corrosion of cast iron has been found to be the most predominant,

which is linked to almost all pipe failures (Misiunas, 2005).

Global data shows that, on average, cast iron has been the dominating material

for water distribution pipes before the 1960s. Therefore the average age of cast

iron pipes in existing networks has been estimated to be 50 years (Rajani and

Kleiner, 2004; Misiunas, 2005). Due to their long-term use, the aging and deterio-

ration of pipes are inevitable and indeed many failures have been reported world-

wide (Atkinson et al., 2002; Misiunas, 2005; Rajani and Tesfamariam, 2007;

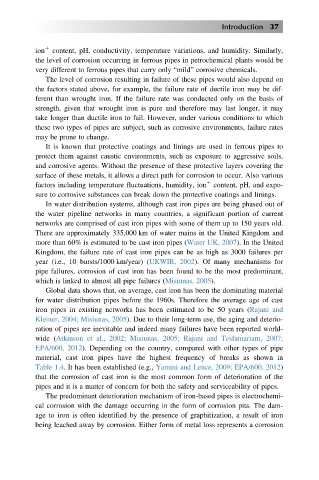

EPA/600, 2012). Depending on the country, compared with other types of pipe

material, cast iron pipes have the highest frequency of breaks as shown in

Table 1.4. It has been established (e.g., Yamini and Lence, 2009; EPA/600, 2012)

that the corrosion of cast iron is the most common form of deterioration of the

pipes and it is a matter of concern for both the safety and serviceability of pipes.

The predominant deterioration mechanism of iron-based pipes is electrochemi-

cal corrosion with the damage occurring in the form of corrosion pits. The dam-

age to iron is often identified by the presence of graphitization, a result of iron

being leached away by corrosion. Either form of metal loss represents a corrosion