Page 84 - Reliability and Maintainability of In service Pipelines

P. 84

Pipeline Inspection and Maintenance 73

2.4.2 CATHODIC PROTECTION

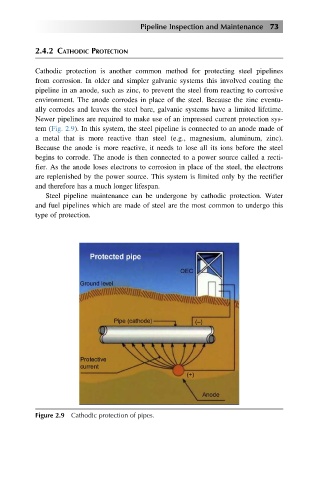

Cathodic protection is another common method for protecting steel pipelines

from corrosion. In older and simpler galvanic systems this involved coating the

pipeline in an anode, such as zinc, to prevent the steel from reacting to corrosive

environment. The anode corrodes in place of the steel. Because the zinc eventu-

ally corrodes and leaves the steel bare, galvanic systems have a limited lifetime.

Newer pipelines are required to make use of an impressed current protection sys-

tem (Fig. 2.9). In this system, the steel pipeline is connected to an anode made of

a metal that is more reactive than steel (e.g., magnesium, aluminum, zinc).

Because the anode is more reactive, it needs to lose all its ions before the steel

begins to corrode. The anode is then connected to a power source called a recti-

fier. As the anode loses electrons to corrosion in place of the steel, the electrons

are replenished by the power source. This system is limited only by the rectifier

and therefore has a much longer lifespan.

Steel pipeline maintenance can be undergone by cathodic protection. Water

and fuel pipelines which are made of steel are the most common to undergo this

type of protection.

Figure 2.9 Cathodic protection of pipes.