Page 121 - Robot Builder's Bonanza

P. 121

90 WORKING WITH PLASTIC

The Ins and Outs of Rigid Expanded PVC

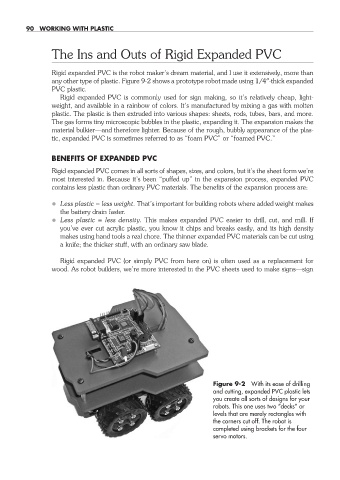

Rigid expanded PVC is the robot maker’s dream material, and I use it extensively, more than

any other type of plastic. Figure 9-2 shows a prototype robot made using 1/4″-thick expanded

PVC plastic.

Rigid expanded PVC is commonly used for sign making, so it’s relatively cheap, light-

weight, and available in a rainbow of colors. It’s manufactured by mixing a gas with molten

plastic. The plastic is then extruded into various shapes: sheets, rods, tubes, bars, and more.

The gas forms tiny microscopic bubbles in the plastic, expanding it. The expansion makes the

material bulkier— and therefore lighter. Because of the rough, bubbly appearance of the plas-

tic, expanded PVC is sometimes referred to as “foam PVC” or “foamed PVC.”

BENEFITS OF EXPANDED PVC

Rigid expanded PVC comes in all sorts of shapes, sizes, and colors, but it’s the sheet form we’re

most interested in. Because it’s been “puffed up” in the expansion process, expanded PVC

contains less plastic than ordinary PVC materials. The benefits of the expansion process are:

• Less plastic = less weight. That’s important for building robots where added weight makes

the battery drain faster.

• Less plastic = less density. This makes expanded PVC easier to drill, cut, and mill. If

you’ve ever cut acrylic plastic, you know it chips and breaks easily, and its high density

makes using hand tools a real chore. The thinner expanded PVC materials can be cut using

a knife; the thicker stuff, with an ordinary saw blade.

Rigid expanded PVC (or simply PVC from here on) is often used as a replacement for

wood. As robot builders, we’re more interested in the PVC sheets used to make signs— sign

Figure 9-2 With its ease of drilling

and cutting, expanded PVC plastic lets

you create all sorts of designs for your

robots. This one uses two “decks” or

levels that are merely rectangles with

the corners cut off. The robot is

completed using brackets for the four

servo motors.

09-chapter-9.indd 90 4/21/11 11:45 AM