Page 126 - Robot Builder's Bonanza

P. 126

MAKING PLASTIC FRAMES 95

Chamfer corners

Center piece

Assembled base

(glue or fasten)

End pieces

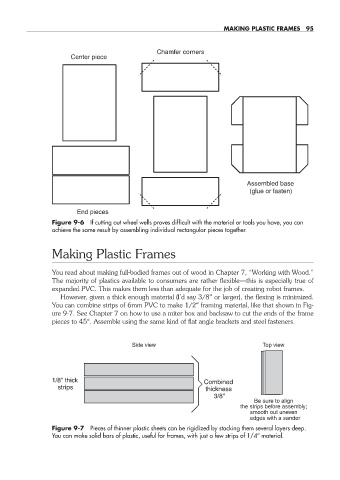

Figure 9-6 If cutting out wheel wells proves difficult with the material or tools you have, you can

achieve the same result by assembling individual rectangular pieces together.

Making Plastic Frames

You read about making full- bodied frames out of wood in Chapter 7, “Working with Wood.”

The majority of plastics available to consumers are rather flexible— this is especially true of

expanded PVC. This makes them less than adequate for the job of creating robot frames.

However, given a thick enough material (I’d say 3/8″ or larger), the flexing is minimized.

You can combine strips of 6mm PVC to make 1/2″ framing material, like that shown in Fig-

ure 9-7. See Chapter 7 on how to use a miter box and backsaw to cut the ends of the frame

pieces to 45°. Assemble using the same kind of flat angle brackets and steel fasteners.

Side view Top view

1/8" thick Combined

strips thickness

3/8"

Be sure to align

the strips before assembly;

smooth out uneven

edges with a sander

Figure 9-7 Pieces of thinner plastic sheets can be rigidized by stacking them several layers deep.

You can make solid bars of plastic, useful for frames, with just a few strips of 1/4″ material.

09-chapter-9.indd 95 4/21/11 11:45 AM