Page 164 - Robot Builder's Bonanza

P. 164

SCREWS, NUTS, AND OTHER FASTENERS 133

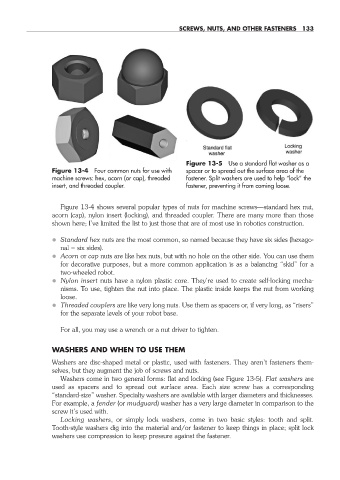

Figure 13-5 Use a standard flat washer as a

Figure 13-4 Four common nuts for use with spacer or to spread out the surface area of the

machine screws: hex, acorn (or cap), threaded fastener. Split washers are used to help “lock” the

insert, and threaded coupler. fastener, preventing it from coming loose.

Figure 13-4 shows several popular types of nuts for machine screws— standard hex nut,

acorn (cap), nylon insert (locking), and threaded coupler. There are many more than those

shown here; I’ve limited the list to just those that are of most use in robotics construction.

• Standard hex nuts are the most common, so named because they have six sides (hexago-

nal = six sides).

• Acorn or cap nuts are like hex nuts, but with no hole on the other side. You can use them

for decorative purposes, but a more common application is as a balancing “skid” for a

two- wheeled robot.

• Nylon insert nuts have a nylon plastic core. They’re used to create self- locking mecha-

nisms. To use, tighten the nut into place. The plastic inside keeps the nut from working

loose.

• Threaded couplers are like very long nuts. Use them as spacers or, if very long, as “risers”

for the separate levels of your robot base.

For all, you may use a wrench or a nut driver to tighten.

WASHERS AND WHEN TO USE THEM

Washers are disc- shaped metal or plastic, used with fasteners. They aren’t fasteners them-

selves, but they augment the job of screws and nuts.

Washers come in two general forms: flat and locking (see Figure 13-5). Flat washers are

used as spacers and to spread out surface area. Each size screw has a corresponding

“standard- size” washer. Specialty washers are available with larger diameters and thicknesses.

For example, a fender (or mudguard) washer has a very large diameter in comparison to the

screw it’s used with.

Locking washers, or simply lock washers, come in two basic styles: tooth and split.

Tooth- style washers dig into the material and/or fastener to keep things in place; split lock

washers use compression to keep pressure against the fastener.

13-chapter-13.indd 133 4/21/11 11:47 AM