Page 166 - Robot Builder's Bonanza

P. 166

BRACKETS 135

Tapping threads involves using a tap, a special tool that looks like a drill bit. It works much

like a self- tapping machine screw, except it makes standard threads, allowing you to then use

regular machine screws.

For tapping to work when using metal, the material must be at least 1/16″ thick, or

roughly the equivalent of two or three threads of the screw— the more threads the better. For

example, when using 4-40 screws, there are 40 threads per inch, which is slightly more than

two threads when using materials of 1/16″ thickness.

When using plastic, the minimum thickness should be no less than four or five threads, and

8 to 10 threads if using expanded PVC. Any fewer and it’s likely the screw will simply strip

the threads out of the hole when the fastener is tightened.

See Chapter 11, “Working with Metal,” for step- by- step instructions on how to use a tap to

FYI

make threaded holes. The technique works for most plastic, too.

Brackets

Brackets are used to hold two or more pieces together, usually— but not always— at right

angles. You might use a bracket to mount a servo motor to a robot base, for example. Brack-

ets come in a variety of shapes and materials. Here’s what you need to know.

ZINC- PLATED STEEL BRACKETS

Though intended to lash two pieces of wood together, steel zinc- plated hardware brackets are

ideal for general robotics construction. These brackets are available in a variety of sizes and

styles at any hardware store. You can use the brackets to build the frame of a robot con-

structed with various stock. See the “Cutting a Frame” section in Chapter 7 for ways brackets

are used in robot construction.

The most common brackets are made of 14- to 18- gauge steel; the lower the gauge num-

ber, the thicker the metal. In order to resist corrosion and rust, the steel is zinc plated, giving

the brackets their common “metallic” look. (Some brackets are plated with brass and are

intended for decorative uses.)

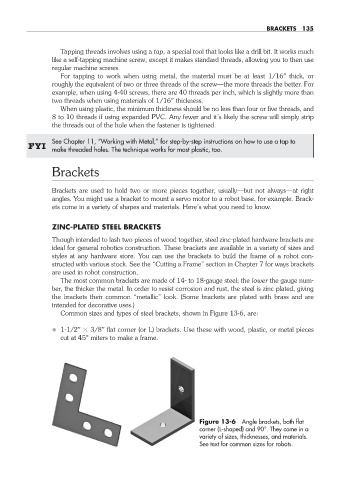

Common sizes and types of steel brackets, shown in Figure 13-6, are:

• 1-1/2″ 3/8″ flat corner (or L) brackets. Use these with wood, plastic, or metal pieces

cut at 45° miters to make a frame.

Figure 13-6 Angle brackets, both flat

corner (L- shaped) and 90°. They come in a

variety of sizes, thicknesses, and materials.

See text for common sizes for robots.

13-chapter-13.indd 135 4/21/11 11:47 AM