Page 254 - Robot Builder's Bonanza

P. 254

MOTOR SPECS 223

motors, such as those used in tape recorders and computer disk drives, operate as slowly as

2000 to 3000 RPM, and there are motors that operate at 12,000 RPM and higher.

You don’t need a lot of speed for most robotic applications. In fact, for DC motors used to

move your robot, the speed of the motor needs to be reduced to no more than 200 or 250

RPM— often even slower.

The easiest way to slow down a motor is to attach some gears to it. This also increases the

turning force (called torque; see the next section), allowing the motor to push bigger robots

or lift heavier objects. Discover more about gears and how they’re used in motors for robots

in Chapter 24, “Mounting Motors and Wheels.”

TORQUE

Torque is the force the motor exerts upon its load— the load is whatever it’s moving. The

higher the torque, the larger the load can be and the faster the motor will spin. Reduce the

torque, and the motor slows down, straining under the workload. Reduce the torque even

more, and the load may prove too demanding for the motor. The motor will stall to a grinding

halt and, in doing so, eat up current— not to mention, put out a lot of heat.

Torque is perhaps the most confusing design aspect of motors. This is not because there is

anything inherently difficult about it, but because motor manufacturers have yet to settle on a

standard means of measurement. Motors made for industry are rated one way; motors for the

military, another. And most motors for consumer or hobby applications come with no torque

ratings at all.

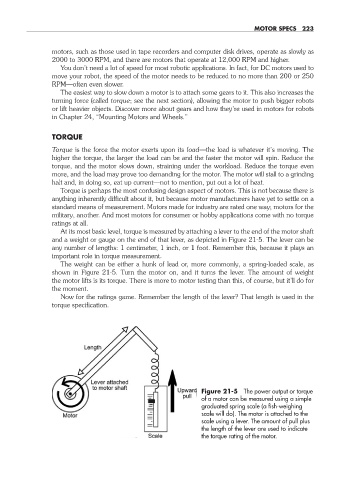

At its most basic level, torque is measured by attaching a lever to the end of the motor shaft

and a weight or gauge on the end of that lever, as depicted in Figure 21- 5. The lever can be

any number of lengths: 1 centimeter, 1 inch, or 1 foot. Remember this, because it plays an

important role in torque measurement.

The weight can be either a hunk of lead or, more commonly, a spring- loaded scale, as

shown in Figure 21- 5. Turn the motor on, and it turns the lever. The amount of weight

the motor lifts is its torque. There is more to motor testing than this, of course, but it’ll do for

the moment.

Now for the ratings game. Remember the length of the lever? That length is used in the

torque specification.

Figure 21- 5 The power output or torque

of a motor can be measured using a simple

graduated spring scale (a fish- weighing

scale will do). The motor is attached to the

scale using a lever. The amount of pull plus

the length of the lever are used to indicate

the torque rating of the motor.

21-chapter-21.indd 223 4/21/11 11:50 AM