Page 307 - Robot Builder's Bonanza

P. 307

276 MOUNTING MOTORS AND WHEELS

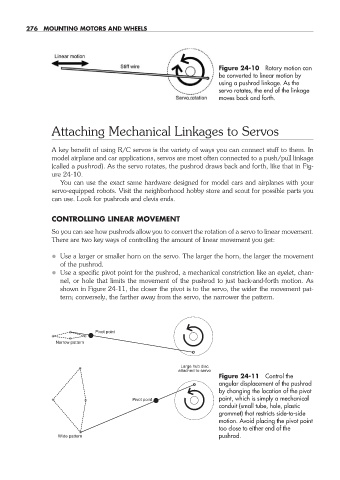

Figure 24- 10 Rotary motion can

be converted to linear motion by

using a pushrod linkage. As the

servo rotates, the end of the linkage

moves back and forth.

Attaching Mechanical Linkages to Servos

A key benefit of using R/C servos is the variety of ways you can connect stuff to them. In

model airplane and car applications, servos are most often connected to a push/pull linkage

(called a pushrod). As the servo rotates, the pushrod draws back and forth, like that in Fig-

ure 24- 10.

You can use the exact same hardware designed for model cars and airplanes with your

servo- equipped robots. Visit the neighborhood hobby store and scout for possible parts you

can use. Look for pushrods and clevis ends.

CONTROLLING LINEAR MOVEMENT

So you can see how pushrods allow you to convert the rotation of a servo to linear movement.

There are two key ways of controlling the amount of linear movement you get:

• Use a larger or smaller horn on the servo. The larger the horn, the larger the movement

of the pushrod.

• Use a specific pivot point for the pushrod, a mechanical constriction like an eyelet, chan-

nel, or hole that limits the movement of the pushrod to just back- and- forth motion. As

shown in Figure 24- 11, the closer the pivot is to the servo, the wider the movement pat-

tern; conversely, the farther away from the servo, the narrower the pattern.

Pivot point

Narrow pattern

Large hub disc

attached to servo

Figure 24- 11 Control the

angular displacement of the pushrod

by changing the location of the pivot

Pivot point point, which is simply a mechanical

conduit (small tube, hole, plastic

grommet) that restricts side- to- side

motion. Avoid placing the pivot point

too close to either end of the

Wide pattern pushrod.

24-chapter-24.indd 276 4/21/11 11:51 AM