Page 246 -

P. 246

4.5 Digital Robot Control 229

where r k is the reference command and w k is the controller input, composed

-1

generally of the tracking error and the plant measured output. Note that z is

interpreted in the time domain as a unit delay of T seconds. The controller

output v k is passed through a hold device to generate the continuous plant

control input u(t).

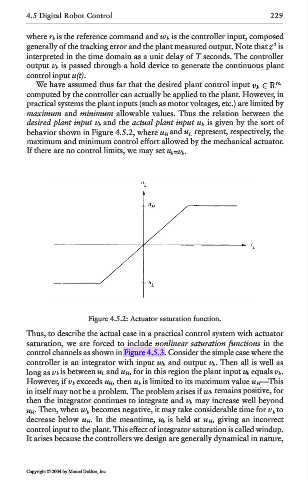

We have assumed thus far that the desired plant control input

computed by the controller can actually be applied to the plant. However, in

practical systems the plant inputs (such as motor voltages, etc.) are limited by

maximum and minimum allowable values. Thus the relation between the

desired plant input v k and the actual plant input u k is given by the sort of

behavior shown in Figure 4.5.2, where u H and u L represent, respectively, the

maximum and minimum control effort allowed by the mechanical actuator.

If there are no control limits, we may set u k =v k .

Figure 4.5.2: Actuator saturation function.

Thus, to describe the actual case in a practical control system with actuator

saturation, we are forced to include nonlinear saturation functions in the

control channels as shown in Figure 4.5.3. Consider the simple case where the

controller is an integrator with input w k and output v k. Then all is well as

long as v k is between u L and u H, for in this region the plant input u k equals v k.

However, if v k exceeds u H, then u k is limited to its maximum value u H—This

in itself may not be a problem. The problem arises if w k remains positive, for

then the integrator continues to integrate and v k may increase well beyond

u H. Then, when w k becomes negative, it may take considerable time for v k to

decrease below u H. In the meantime, u k is held at u H, giving an incorrect

control input to the plant. This effect of integrator saturation is called windup.

It arises because the controllers we design are generally dynamical in nature,

Copyright © 2004 by Marcel Dekker, Inc.