Page 29 -

P. 29

10 Commercial Robot Manipulators

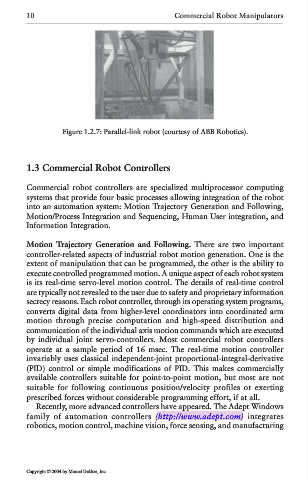

Figure 1.2.7: Parallel-link robot (courtesy of ABB Robotics).

1.3 Commercial Robot Controllers

Commercial robot controllers are specialized multiprocessor computing

systems that provide four basic processes allowing integration of the robot

into an automation system: Motion Trajectory Generation and Following,

Motion/Process Integration and Sequencing, Human User integration, and

Information Integration.

Motion Trajectory Generation and Following. There are two important

controller-related aspects of industrial robot motion generation. One is the

extent of manipulation that can be programmed, the other is the ability to

execute controlled programmed motion. A unique aspect of each robot system

is its real-time servo-level motion control. The details of real-time control

are typically not revealed to the user due to safety and proprietary information

secrecy reasons. Each robot controller, through its operating system programs,

converts digital data from higher-level coordinators into coordinated arm

motion through precise computation and high-speed distribution and

communication of the individual axis motion commands which are executed

by individual joint servo-controllers. Most commercial robot controllers

operate at a sample period of 16 msec. The real-time motion controller

invariably uses classical independent-joint proportional-integral-derivative

(PID) control or simple modifications of PID. This makes commercially

available controllers suitable for point-to-point motion, but most are not

suitable for following continuous position/velocity profiles or exerting

prescribed forces without considerable programming effort, if at all.

Recently, more advanced controllers have appeared. The Adept Windows

family of automation controllers (http://www.adept.com) integrates

robotics, motion control, machine vision, force sensing, and manufacturing

Copyright © 2004 by Marcel Dekker, Inc.