Page 26 - Rock Mechanics For Underground Mining

P. 26

ROCK MECHANICS AND MINING ENGINEERING

or by fractured ore temporarily retained in contact with mined stope walls. The second

type of mine configuration recognised by Thomas is a caving structure, generated by

mining methods such as block caving and sublevel caving. In these cases, no support is

provided in the mined space, which fills spontaneously with fragmented and displaced

orebody and cover rock.

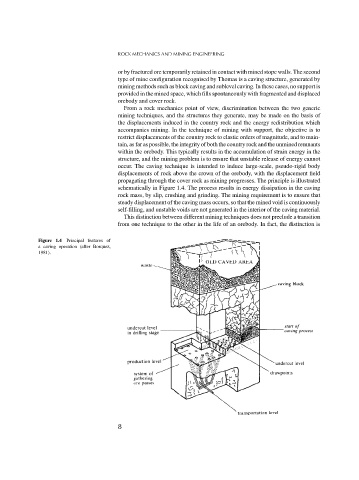

From a rock mechanics point of view, discrimination between the two generic

mining techniques, and the structures they generate, may be made on the basis of

the displacements induced in the country rock and the energy redistribution which

accompanies mining. In the technique of mining with support, the objective is to

restrict displacements of the country rock to elastic orders of magnitude, and to main-

tain, as far as possible, the integrity of both the country rock and the unmined remnants

within the orebody. This typically results in the accumulation of strain energy in the

structure, and the mining problem is to ensure that unstable release of energy cannot

occur. The caving technique is intended to induce large-scale, pseudo-rigid body

displacements of rock above the crown of the orebody, with the displacement field

propagating through the cover rock as mining progresses. The principle is illustrated

schematically in Figure 1.4. The process results in energy dissipation in the caving

rock mass, by slip, crushing and grinding. The mining requirement is to ensure that

steady displacement of the caving mass occurs, so that the mined void is continuously

self-filling, and unstable voids are not generated in the interior of the caving material.

This distinction between different mining techniques does not preclude a transition

from one technique to the other in the life of an orebody. In fact, the distinction is

Figure 1.4 Principal features of

a caving operation (after Borquez,

1981).

8