Page 25 - Rock Mechanics For Underground Mining

P. 25

UNDERGROUND MINING

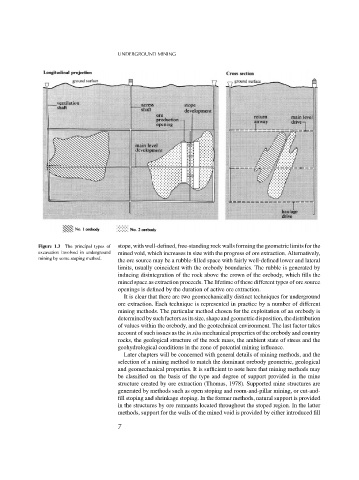

Figure 1.3 The principal types of stope, with well-defined, free-standing rock walls forming the geometric limits for the

excavation involved in underground mined void, which increases in size with the progress of ore extraction. Alternatively,

mining by some stoping method.

the ore source may be a rubble-filled space with fairly well-defined lower and lateral

limits, usually coincident with the orebody boundaries. The rubble is generated by

inducing disintegration of the rock above the crown of the orebody, which fills the

mined space as extraction proceeds. The lifetime of these different types of ore source

openings is defined by the duration of active ore extraction.

It is clear that there are two geomechanically distinct techniques for underground

ore extraction. Each technique is represented in practice by a number of different

mining methods. The particular method chosen for the exploitation of an orebody is

determined bysuch factors as itssize, shape and geometric disposition, thedistribution

of values within the orebody, and the geotechnical environment. The last factor takes

account of such issues as the in situ mechanical properties of the orebody and country

rocks, the geological structure of the rock mass, the ambient state of stress and the

geohydrological conditions in the zone of potential mining influence.

Later chapters will be concerned with general details of mining methods, and the

selection of a mining method to match the dominant orebody geometric, geological

and geomechanical properties. It is sufficient to note here that mining methods may

be classified on the basis of the type and degree of support provided in the mine

structure created by ore extraction (Thomas, 1978). Supported mine structures are

generated by methods such as open stoping and room-and-pillar mining, or cut-and-

fill stoping and shrinkage stoping. In the former methods, natural support is provided

in the structures by ore remnants located throughout the stoped region. In the latter

methods, support for the walls of the mined void is provided by either introduced fill

7