Page 389 - Rock Mechanics For Underground Mining

P. 389

COMPONENTS OF A SUPPORTED MINE STRUCTURE

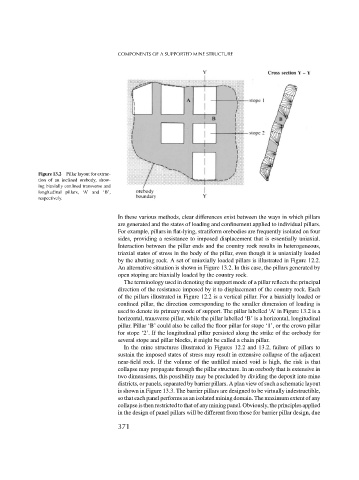

Figure 13.2 Pillar layout for extrac-

tion of an inclined orebody, show-

ing biaxially confined transverse and

longitudinal pillars, ‘A’ and ‘B’,

respectively.

In these various methods, clear differences exist between the ways in which pillars

are generated and the states of loading and confinement applied to individual pillars.

For example, pillars in flat-lying, stratiform orebodies are frequently isolated on four

sides, providing a resistance to imposed displacement that is essentially uniaxial.

Interaction between the pillar ends and the country rock results in heterogeneous,

triaxial states of stress in the body of the pillar, even though it is uniaxially loaded

by the abutting rock. A set of uniaxially loaded pillars is illustrated in Figure 12.2.

An alternative situation is shown in Figure 13.2. In this case, the pillars generated by

open stoping are biaxially loaded by the country rock.

The terminology used in denoting the support mode of a pillar reflects the principal

direction of the resistance imposed by it to displacement of the country rock. Each

of the pillars illustrated in Figure 12.2 is a vertical pillar. For a biaxially loaded or

confined pillar, the direction corresponding to the smaller dimension of loading is

used to denote its primary mode of support. The pillar labelled ‘A’ in Figure 13.2 is a

horizontal, transverse pillar, while the pillar labelled ‘B’ is a horizontal, longitudinal

pillar. Pillar ‘B’ could also be called the floor pillar for stope ‘1’, or the crown pillar

for stope ‘2’. If the longitudinal pillar persisted along the strike of the orebody for

several stope and pillar blocks, it might be called a chain pillar.

In the mine structures illustrated in Figures 12.2 and 13.2, failure of pillars to

sustain the imposed states of stress may result in extensive collapse of the adjacent

near-field rock. If the volume of the unfilled mined void is high, the risk is that

collapse may propagate through the pillar structure. In an orebody that is extensive in

two dimensions, this possibility may be precluded by dividing the deposit into mine

districts, or panels, separated by barrier pillars. A plan view of such a schematic layout

is shown in Figure 13.3. The barrier pillars are designed to be virtually indestructible,

so that each panel performs as an isolated mining domain. The maximum extent of any

collapse is then restricted to that of any mining panel. Obviously, the principles applied

in the design of panel pillars will be different from those for barrier pillar design, due

371