Page 460 - Rock Mechanics For Underground Mining

P. 460

LONGWALL AND CAVING MINING METHODS

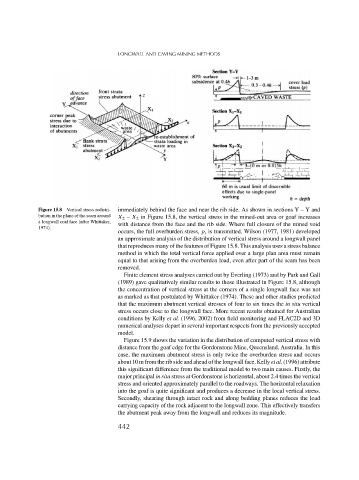

Figure 15.8 Vertical stress redistri- immediately behind the face and near the rib side. As shown in sectionsY–Yand

bution in the plane of the seam around X 2 – X 2 in Figure 15.8, the vertical stress in the mined-out area or goaf increases

a longwall coal face (after Whittaker,

with distance from the face and the rib side. Where full closure of the mined void

1974).

occurs, the full overburden stress, p, is transmitted. Wilson (1977, 1981) developed

an approximate analysis of the distribution of vertical stress around a longwall panel

that reproduces many of the features of Figure 15.8. This analysis uses a stress balance

method in which the total vertical force applied over a large plan area must remain

equal to that arising from the overburden load, even after part of the seam has been

removed.

Finite element stress analyses carried out by Everling (1973) and by Park and Gall

(1989) gave qualitatively similar results to those illustrated in Figure 15.8, although

the concentration of vertical stress at the corners of a single longwall face was not

as marked as that postulated by Whittaker (1974). These and other studies predicted

that the maximum abutment vertical stresses of four to six times the in situ vertical

stress occurs close to the longwall face. More recent results obtained for Australian

conditions by Kelly et al. (1996, 2002) from field monitoring and FLAC2D and 3D

numerical analyses depart in several important respects from the previously accepted

model.

Figure 15.9 shows the variation in the distribution of computed vertical stress with

distance from the goaf edge for the Gordonstone Mine, Queensland, Australia. In this

case, the maximum abutment stress is only twice the overburden stress and occurs

about 10 m from the rib side and ahead of the longwall face. Kellyet al. (1996) attribute

this significant difference from the traditional model to two main causes. Firstly, the

major principal in situ stress at Gordonstone is horizontal, about 2.4 times the vertical

stress and oriented approximately parallel to the roadways. The horizontal relaxation

into the goaf is quite significant and produces a decrease in the local vertical stress.

Secondly, shearing through intact rock and along bedding planes reduces the load

carrying capacity of the rock adjacent to the longwall zone. This effectively transfers

the abutment peak away from the longwall and reduces its magnitude.

442