Page 173 - Root Cause Failure Analysis

P. 173

Dust Collectors 161

Configuration

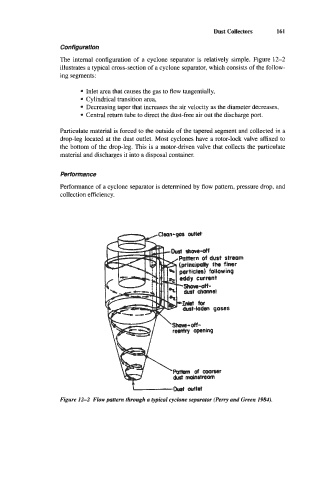

The internal configuration of a cyclone separator is relatively simple. Figure 12-2

illustrates a typical cross-section of a cyclone separator, which consists of the follow-

ing segments:

Inlet area that causes the gas to flow tangentially,

Cylindrical transition area,

Decreasing taper that increases the air velocity as the diameter decreases,

Central return tube to direct the dust-free air out the discharge port.

Particulate material is forced to the outside of the tapered segment and collected in a

drop-leg located at the dust outlet. Most cyclones have a rotor-lock valve affixed to

the bottom of the drop-leg. This is a motor-driven valve that collects the particulate

material and discharges it into a disposal container.

performance

Performance of a cyclone separator is determined by flow pattern, pressure drop, and

collection efficiency.

L O w f outlet

Figure 12-2 Flow pattern through a lypical cyclone separator (Perry and Green 1984).