Page 178 - Root Cause Failure Analysis

P. 178

166 Root Cause Failure Analysis

Bearing-Support Shafts

Many roll failures can be directly attributed to poor shaft design. In these cases, the

total span from the roll body to the bearing-support point is too long for the shaft

diameter. As a result, the bending moment imparted by the roll during normal opera-

tion creates an alternating compression-tension stress on the shafts. The typical failure

point is where the shaft diameter changes.

Both the total bearing span from inboard to outboard bearing and the cantilevered

spans from the roll body to the bearing-support point must be carefully considered

when designing a process roll. The design must withstand the total forces generated in

both normal and abnormal operation.

The fact that roll necks generally are relatively long and use multiple shaft-diameter

reductions causes two problems. First, the long span and reduced diameter weaken

the shaft, increasing the probability of excessive bending and the potential for prema-

ture failure. The second problem is the 90" corner created by the diameter reduction.

This comer creates stress points that work harden when the roll is subjected to bend-

ing moments and strip tension.

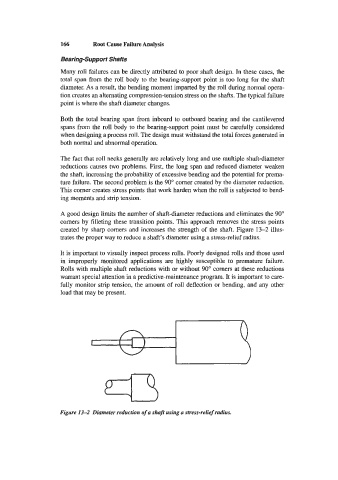

A good design limits the number of shaft-diameter reductions and eliminates the 90"

comers by filleting these transition points. This approach removes the stress points

created by sharp corners and increases the strength of the shaft. Figure 13-2 illus-

trates the proper way to reduce a shaft's diameter using a stress-relief radius.

It is important to visually inspect process rolls. Poorly designed rolls and those used

in improperly monitored applications are highly susceptible to premature failure.

Rolls with multiple shaft reductions with or without 90" corners at these reductions

warrant special attention in a predictive-maintenance program. It is important to care-

fully monitor strip tension, the amount of roll deflection or bending, and any other

load that may be present.

Figure 13-2 Diameter reduction of a shfl using a stress-relief radius.