Page 180 - Root Cause Failure Analysis

P. 180

168 Root Cause Failure Analysis

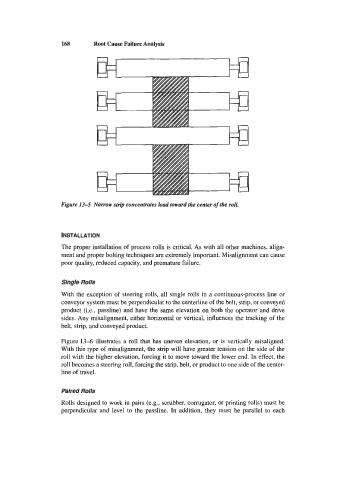

Figure 13-5 Narrow strip concentrates load toward the center of the roll.

INSTALLATION

The proper installation of process rolls is critical. As with all other machines, align-

ment and proper bolting techniques are extremely important. Misalignment can cause

poor quality, reduced capacity, and premature failure.

Single Rolls

With the exception of steering rolls, all single rolls in a continuous-process line or

conveyor system must be perpendicular to the centerline of the belt, strip, or conveyed

product (i.e., passline) and have the same elevation on both the operator and drive

sides. Any misalignment, either horizontal or vertical, influences the tracking of the

belt, strip, and conveyed product.

Figure 13-6 illustrates a roll that has uneven elevation, or is vertically misaligned.

With this type of misalignment, the strip will have greater tension on the side of the

roll with the higher elevation, forcing it to move toward the lower end. In effect, the

roll becomes a steering roll, forcing the strip, belt, or product to one side of the center-

line of travel.

Paired Rolls

Rolls designed to work in pairs (e.g., scrubber, corrugator, or printing rolls) must be

perpendicular and level to the passline. In addition, they must be parallel to each