Page 200 - Root Cause Failure Analysis

P. 200

188 Root Cause Failure Analysis

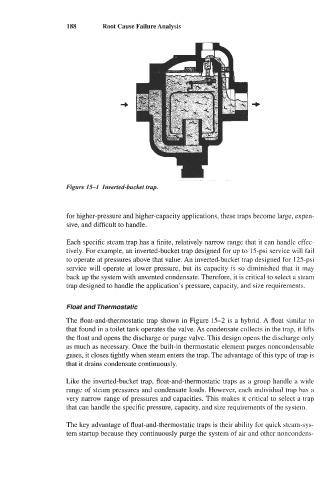

Figure 15-Z Inverted-bucket trap.

for higher-pressure and higher-capacity applications, these traps become large, expen-

sive. and difficult to handle.

Each specific steam trap has a finite, relatively narrow range that it can handle effec-

tively. For example, an inverted-bucket trap designed for up to 15-psi service will fail

to operate at pressures above that value. An inverted-bucket trap designed for 125-psi

service will operate at lower pressure, but its capacity is so diminished that it may

back up the system with unvented condensate. Therefore, it is critical to select a steam

trap designed to handle the application’s pressure, capacity, and size requirements.

Float and Thermostatic

The float-and-thermostatic trap shown in Figure 15-2 is a hybrid. A float similar to

that found in a toilet tank operates the valve. As condensate collects in the trap, it lifts

the float and opens the discharge or purge valve. This design opens the discharge only

as much as necessary. Once the built-in thermostatic element purges noncondensable

gases, it closes tightly when steam enters the trap. The advantage of this type of trap is

that it drains condensate continuously.

Like the inverted-bucket trap, float-and-thermostatic traps as a group handle a wide

range of steam pressures and condensate loads. However, each individual trap has a

very narrow range of pressures and capacities. This makes it critical to select a trap

that can handle the specific pressure, capacity, and size requirements of the system.

The key advantage of float-and-thermostatic traps is their ability for quick steam-sys-

tem startup because they continuously purge the system of air and other noncondens-