Page 201 - Root Cause Failure Analysis

P. 201

Steam Traps 189

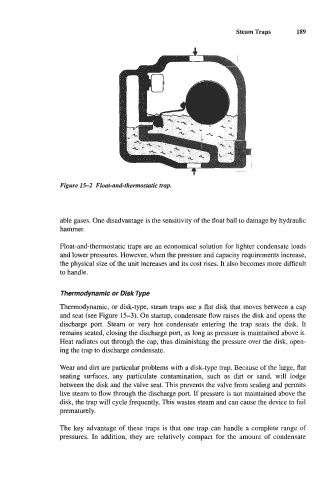

Figure 15-2 Float-ad-thermostatic trap.

able gases. One disadvantage is the sensitivity of the float ball to damage by hydraulic

hammer.

Float-and-thermostatic traps are an economical solution for lighter condensate loads

and lower pressures. However, when the pressure and capacity requirements increase,

the physical size of the unit increases and its cost rises. It also becomes more difficult

to handle.

Thermodynamic or Disk Type

Thermodynamic, or disk-type, steam traps use a flat disk that moves between a cap

and seat (see Figure 15-3). On startup, condensate flow raises the disk and opens the

discharge port. Steam or very hot condensate entering the trap seats the disk. It

remains seated, closing the discharge port, as long as pressure is maintained above it.

Heat radiates out through the cap, thus diminishing the pressure over the disk, open-

ing the trap to discharge condensate.

Wear and dirt are particular problems with a disk-type trap. Because of the large, flat

seating surfaces, any particulate contamination, such as dirt or sand, will lodge

between the disk and the valve seat. This prevents the valve from sealing and permits

live steam to flow through the discharge port. If pressure is not maintained above the

disk, the trap will cycle frequently. This wastes steam and can cause the device to fail

prematurely.

The key advantage of these traps is that one trap can handle a complete range of

pressures. In addition, they are relatively compact for the amount of condensate