Page 27 - Root Cause Failure Analysis

P. 27

18 Root Cause Failure Analysis

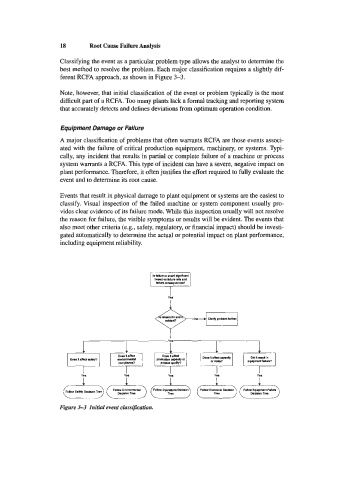

Classifying the event as a particular problem type allows the analyst to determine the

best method to resolve the problem. Each major classification requires a slightly dif-

ferent RCFA approach, as shown in Figure 3-3.

Note, however, that initial classification of the event or problem typically is the most

difficult part of a RCFA. Too many plants lack a formal tracking and reporting system

that accurately detects and defines deviations from optimum operation condition.

Equipment Damage or Failure

A major classification of problems that often warrants RCFA are those events associ-

ated with the failure of critical production equipment, machinery, or systems. Ifrpi-

cally, any incident that results in partial or complete failure of a machine or process

system warrants a RCFA. This type of incident can have a severe, negative impact on

plant performance. Therefore, it often justifies the effort required to fully evaluate the

event and to determine its root cause.

Events that result in physical damage to plant equipment or systems are the easiest to

classify. Visual inspection of the failed machine or system component usually pro-

vides clear evidence of its failure mode. While this inspection usually will not resolve

the reason for failure, the visible symptoms or results will be evident. The events that

also meet other criteria (e.g., safety, regulatory, or financial impact) should be investi-

gated automatically to determine the actual or potential impact on plant performance.

including equipment reliability.

VU Yb. Y;. Y&

I I I I