Page 91 - Root Cause Failure Analysis

P. 91

82 Root Cause Failure Analysis

h

- Flow

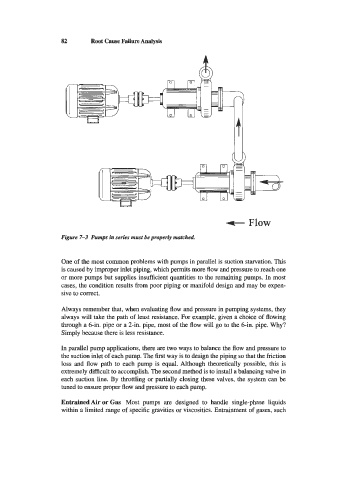

Figure 7-3 Pumps in series must be properly matched.

One of the most common problems with pumps in parallel is suction starvation. This

is caused by improper inlet piping, which permits more flow and pressure to reach one

or more pumps but supplies insufficient quantities to the remaining pumps. In most

cases, the condition results from poor piping or manifold design and may be expen-

sive to correct.

Always remember that, when evaluating flow and pressure in pumping systems, they

always will take the path of least resistance. For example, given a choice of flowing

through a 6-in. pipe or a 2-in. pipe, most of the flow will go to the 6-in. pipe. Why?

Simply because there is less resistance.

In parallel pump applications, there are two ways to balance the flow and pressure to

the suction inlet of each pump. The first way is to design the piping so that the friction

loss and flow path to each pump is equal. Although theoretically possible, this is

extremely difficult to accomplish. The second method is to install a balancing valve in

each suction line. By throttling or partially closing these valves, the system can be

tuned to ensure proper flow and pressure to each pump.

Entrained Air or Gas Most pumps are designed to handle single-phase liquids

within a limited range of specific gravities or viscosities. Entrainment of gases, such