Page 27 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 27

Rotating Machinery: Practical Solutions

example, centrifugal pumps should have a block off test run to

determine the actual head produced. The voltage and amperes

should be measured and the actual horsepower consumed calcu-

lated. These data should be plotted on the pump’s performance

curve and a record maintained.

A comprehensive listing of all equipment should be as-

sembled, and any missing data should be requested from the

manufacturer. Further, this will assist in determining what spare

parts need to be carried in inventory, and what parts may be in-

terchangeable.

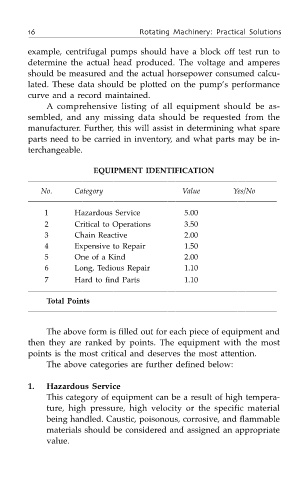

EQUIPMENT IDENTIFICATION

————————————————————————————————

No. Category Value Yes/No

————————————————————————————————

1 Hazardous Service 5.00

2 Critical to Operations 3.50

3 Chain Reactive 2.00

4 Expensive to Repair 1.50

5 One of a Kind 2.00

6 Long, Tedious Repair 1.10

7 Hard to find Parts 1.10

————————————————————————————————

Total Points

————————————————————————————————

The above form is filled out for each piece of equipment and

then they are ranked by points. The equipment with the most

points is the most critical and deserves the most attention.

The above categories are further defined below:

1. Hazardous Service

This category of equipment can be a result of high tempera-

ture, high pressure, high velocity or the specific material

being handled. Caustic, poisonous, corrosive, and flammable

materials should be considered and assigned an appropriate

value.