Page 43 - Sensing, Intelligence, Motion : How Robots and Humans Move in an Unstructured World

P. 43

18 MOTION PLANNING—INTRODUCTION

When we develop our motion planning algorithms based on tactile sensing, this

does not mean we suggest tactile sensing as a preferable sensing media, nor does

it mean that the algorithms are applicable solely to tactile sensing. As we will

see, expanding algorithms to more complex sensing is usually relatively easy, and

usually results in higher efficiency.

1.2.4 Degrees of Freedom. Coordinate Systems

It is known from mechanics that depending on space dimensionality and object

complexity, there is a minimum number of independent variables one needs to

define the object’s position and orientation in a unique way. These variables are

called the object’s degrees of freedom (DOF). The reference (coordinate) system

expressed in terms of object’s DOF is called the configuration space (C-space).

C-space is hence a special representation of the robot workspace (W-space).

From a textbook on mechanics, the minimum number of DOF that a rigid body

needs for an arbitrary motion is

In 2D, if only translation is allowed: 2

In 2D, translation plus orientation allowed: 3

In 3D, if only translation is allowed: 3

In 3D, translation plus orientation allowed: 6

For example, for a planar (2D) case with a rigid object free to translate and

rotate, the object is defined by three DOF (x, y, θ): two Cartesian coordinates

(x, y) that define the object’s position, plus its orientation angle θ.

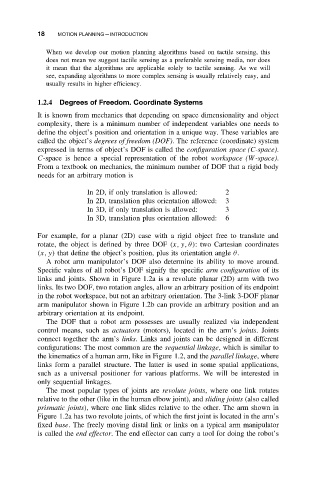

A robot arm manipulator’s DOF also determine its ability to move around.

Specific values of all robot’s DOF signify the specific arm configuration of its

links and joints. Shown in Figure 1.2a is a revolute planar (2D) arm with two

links. Its two DOF, two rotation angles, allow an arbitrary position of its endpoint

in the robot workspace, but not an arbitrary orientation. The 3-link 3-DOF planar

arm manipulator shown in Figure 1.2b can provide an arbitrary position and an

arbitrary orientation at its endpoint.

The DOF that a robot arm possesses are usually realized via independent

control means, such as actuators (motors), located in the arm’s joints. Joints

connect together the arm’s links. Links and joints can be designed in different

configurations: The most common are the sequential linkage, which is similar to

the kinematics of a human arm, like in Figure 1.2, and the parallel linkage,where

links form a parallel structure. The latter is used in some spatial applications,

such as a universal positioner for various platforms. We will be interested in

only sequential linkages.

The most popular types of joints are revolute joints, where one link rotates

relative to the other (like in the human elbow joint), and sliding joints (also called

prismatic joints), where one link slides relative to the other. The arm shown in

Figure 1.2a has two revolute joints, of which the first joint is located in the arm’s

fixed base. The freely moving distal link or links on a typical arm manipulator

is called the end effector. The end effector can carry a tool for doing the robot’s