Page 160 - Sensors and Control Systems in Manufacturing

P. 160

Classification and Types of Sensors

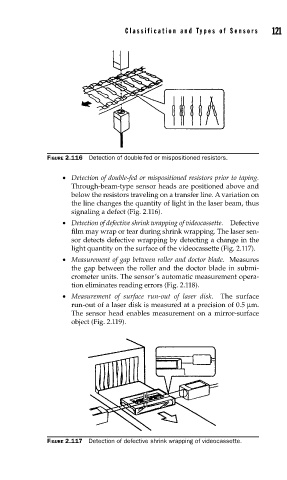

FIGURE 2.116 Detection of double-fed or mispositioned resistors. 121

• Detection of double-fed or mispositioned resistors prior to taping.

Through-beam-type sensor heads are positioned above and

below the resistors traveling on a transfer line. A variation on

the line changes the quantity of light in the laser beam, thus

signaling a defect (Fig. 2.116).

• Detection of defective shrink wrapping of videocassette. Defective

film may wrap or tear during shrink wrapping. The laser sen-

sor detects defective wrapping by detecting a change in the

light quantity on the surface of the videocassette (Fig. 2.117).

• Measurement of gap between roller and doctor blade. Measures

the gap between the roller and the doctor blade in submi-

crometer units. The sensor’s automatic measurement opera-

tion eliminates reading errors (Fig. 2.118).

• Measurement of surface run-out of laser disk. The surface

run-out of a laser disk is measured at a precision of 0.5 μm.

The sensor head enables measurement on a mirror-surface

object (Fig. 2.119).

FIGURE 2.117 Detection of defective shrink wrapping of videocassette.