Page 173 - Sensors and Control Systems in Manufacturing

P. 173

134

Cha p te r

T h ree

+

+

LED Photo

Detector

Output

Contact

Source Detector

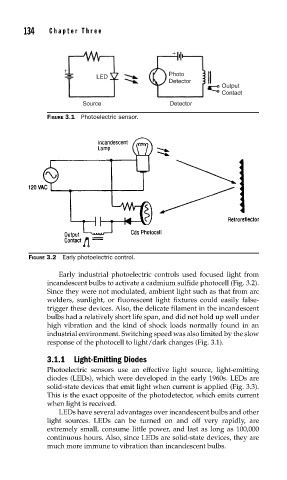

FIGURE 3.1 Photoelectric sensor.

FIGURE 3.2 Early photoelectric control.

Early industrial photoelectric controls used focused light from

incandescent bulbs to activate a cadmium sulfide photocell (Fig. 3.2).

Since they were not modulated, ambient light such as that from arc

welders, sunlight, or fluorescent light fixtures could easily false-

trigger these devices. Also, the delicate filament in the incandescent

bulbs had a relatively short life span, and did not hold up well under

high vibration and the kind of shock loads normally found in an

industrial environment. Switching speed was also limited by the slow

response of the photocell to light/dark changes (Fig. 3.1).

3.1.1 Light-Emitting Diodes

Photoelectric sensors use an effective light source, light-emitting

diodes (LEDs), which were developed in the early 1960s. LEDs are

solid-state devices that emit light when current is applied (Fig. 3.3).

This is the exact opposite of the photodetector, which emits current

when light is received.

LEDs have several advantages over incandescent bulbs and other

light sources. LEDs can be turned on and off very rapidly, are

extremely small, consume little power, and last as long as 100,000

continuous hours. Also, since LEDs are solid-state devices, they are

much more immune to vibration than incandescent bulbs.