Page 169 - Sensors and Control Systems in Manufacturing

P. 169

130

Cha p te r

T w o

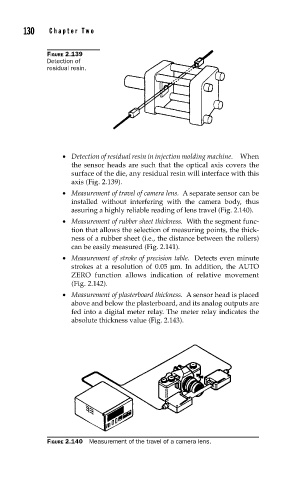

FIGURE 2.139

Detection of

residual resin.

• Detection of residual resin in injection molding machine. When

the sensor heads are such that the optical axis covers the

surface of the die, any residual resin will interface with this

axis (Fig. 2.139).

• Measurement of travel of camera lens. A separate sensor can be

installed without interfering with the camera body, thus

assuring a highly reliable reading of lens travel (Fig. 2.140).

• Measurement of rubber sheet thickness. With the segment func-

tion that allows the selection of measuring points, the thick-

ness of a rubber sheet (i.e., the distance between the rollers)

can be easily measured (Fig. 2.141).

• Measurement of stroke of precision table. Detects even minute

strokes at a resolution of 0.05 μm. In addition, the AUTO

ZERO function allows indication of relative movement

(Fig. 2.142).

• Measurement of plasterboard thickness. A sensor head is placed

above and below the plasterboard, and its analog outputs are

fed into a digital meter relay. The meter relay indicates the

absolute thickness value (Fig. 2.143).

FIGURE 2.140 Measurement of the travel of a camera lens.