Page 223 - Sensors and Control Systems in Manufacturing

P. 223

184

T h ree

Cha p te r

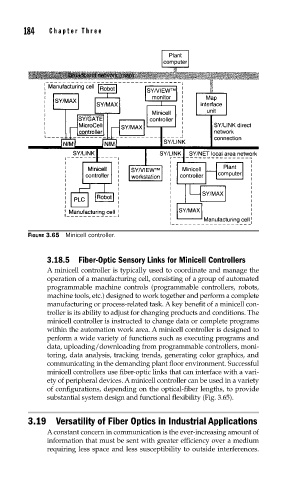

FIGURE 3.65 Minicell controller.

3.18.5 Fiber-Optic Sensory Links for Minicell Controllers

A minicell controller is typically used to coordinate and manage the

operation of a manufacturing cell, consisting of a group of automated

programmable machine controls (programmable controllers, robots,

machine tools, etc.) designed to work together and perform a complete

manufacturing or process-related task. A key benefit of a minicell con-

troller is its ability to adjust for changing products and conditions. The

minicell controller is instructed to change data or complete programs

within the automation work area. A minicell controller is designed to

perform a wide variety of functions such as executing programs and

data, uploading/downloading from programmable controllers, moni-

toring, data analysis, tracking trends, generating color graphics, and

communicating in the demanding plant floor environment. Successful

minicell controllers use fiber-optic links that can interface with a vari-

ety of peripheral devices. A minicell controller can be used in a variety

of configurations, depending on the optical-fiber lengths, to provide

substantial system design and functional flexibility (Fig. 3.65).

3.19 Versatility of Fiber Optics in Industrial Applications

A constant concern in communication is the ever-increasing amount of

information that must be sent with greater efficiency over a medium

requiring less space and less susceptibility to outside interferences.