Page 429 - Sensors and Control Systems in Manufacturing

P. 429

Sensors in Flexible Manufacturing Systems

consideration is selecting the optimum resolution for the task to be 383

executed. There is a tendency to assume that the higher the resolu-

tion, the greater the application range for the system. However, con-

siderable success has been achieved with a resolution as low as 50 ×

50 picture elements. With serial processing architectures, this resolu-

tion will generate sufficient gray-scale data to test the ingenuity of

image processing algorithms. Should its processing time fall below

0.5 s, an algorithm can be used for robots associated with handling.

However, in welding applications, the image processing time must

be faster.

8.3 Robot Control through Vision Sensors

An increasing number of manufacturing processes rely on machine-

vision sensors for automation. The tasks for which vision sensors are

used vary widely in scope and difficulty. Robotic applications in

which vision sensing has been used successfully include inspection,

alignment, object identification, and character recognition.

Human vision involves transformation, analysis, and interpreta-

tion of images. Machine-vision sensing can be explained in terms of

the same functions: image transformation, image analysis, and image

interpretation.

8.3.1 Image Transformation

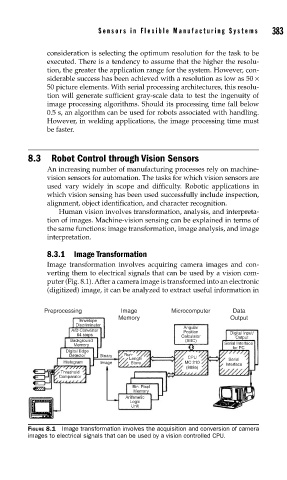

Image transformation involves acquiring camera images and con-

verting them to electrical signals that can be used by a vision com-

puter (Fig. 8.1). After a camera image is transformed into an electronic

(digitized) image, it can be analyzed to extract useful information in

Preprocessing Image Microcomputer Data

Memory Output

Envelope

Discriminator Angular

A/D Converter Position

64 steps Calculator Digital Input/

Background (SBC) Output

Memory Serial Interface

for PC

Digital Edge

Detector Binary Run-

Length CPU Serial

Histogram Image Store MC 210 Interface

(8085)

Threshold

Comparator

Bin. Pixel

Memory

Arithmetic

Logic

Unit

FIGURE 8.1 Image transformation involves the acquisition and conversion of camera

images to electrical signals that can be used by a vision controlled CPU.