Page 431 - Sensors and Control Systems in Manufacturing

P. 431

(a) Sensors in Flexible Manufacturing Systems 385

(b)

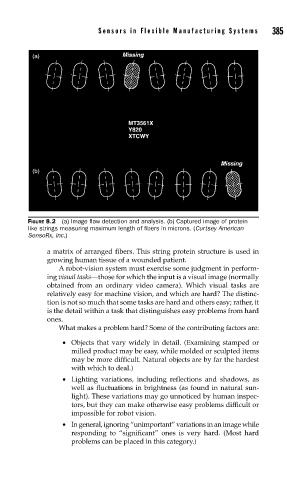

FIGURE 8.2 (a) Image fl aw detection and analysis. (b) Captured image of protein

like strings measuring maximum length of fi bers in microns. (Curtsey American

SensoRx, inc.)

a matrix of arranged fibers. This string protein structure is used in

growing human tissue of a wounded patient.

A robot-vision system must exercise some judgment in perform-

ing visual tasks—those for which the input is a visual image (normally

obtained from an ordinary video camera). Which visual tasks are

relatively easy for machine vision, and which are hard? The distinc-

tion is not so much that some tasks are hard and others easy; rather, it

is the detail within a task that distinguishes easy problems from hard

ones.

What makes a problem hard? Some of the contributing factors are:

• Objects that vary widely in detail. (Examining stamped or

milled product may be easy, while molded or sculpted items

may be more difficult. Natural objects are by far the hardest

with which to deal.)

• Lighting variations, including reflections and shadows, as

well as fluctuations in brightness (as found in natural sun-

light). These variations may go unnoticed by human inspec-

tors, but they can make otherwise easy problems difficult or

impossible for robot vision.

• In general, ignoring “unimportant” variations in an image while

responding to “significant” ones is very hard. (Most hard

problems can be placed in this category.)