Page 437 - Sensors and Control Systems in Manufacturing

P. 437

Sensors in Flexible Manufacturing Systems

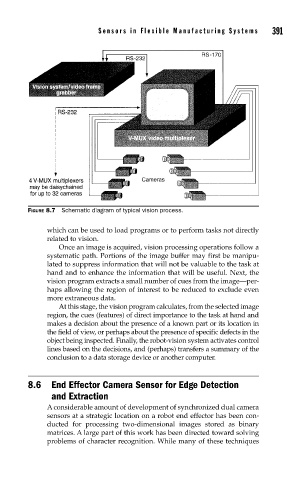

FIGURE 8.7 Schematic diagram of typical vision process. 391

which can be used to load programs or to perform tasks not directly

related to vision.

Once an image is acquired, vision processing operations follow a

systematic path. Portions of the image buffer may first be manipu-

lated to suppress information that will not be valuable to the task at

hand and to enhance the information that will be useful. Next, the

vision program extracts a small number of cues from the image—per-

haps allowing the region of interest to be reduced to exclude even

more extraneous data.

At this stage, the vision program calculates, from the selected image

region, the cues (features) of direct importance to the task at hand and

makes a decision about the presence of a known part or its location in

the field of view, or perhaps about the presence of specific defects in the

object being inspected. Finally, the robot-vision system activates control

lines based on the decisions, and (perhaps) transfers a summary of the

conclusion to a data storage device or another computer.

8.6 End Effector Camera Sensor for Edge Detection

and Extraction

A considerable amount of development of synchronized dual camera

sensors at a strategic location on a robot end effector has been con-

ducted for processing two-dimensional images stored as binary

matrices. A large part of this work has been directed toward solving

problems of character recognition. While many of these techniques