Page 442 - Sensors and Control Systems in Manufacturing

P. 442

396

Cha p te r

Ei g h t

objects jumbled together in a pallet. In two-dimensional tasks, the

uncertainty is in the location of an object in a plane parallel to the image

plane of the camera sensor. This restriction implies a simple one-to-

one correspondence between sizes and orientations in the image, on

the one hand, and sizes and orientations in the plane of the object, on

the other.

This class of two-dimensional tasks can be partitioned into four

subclasses that are defined in terms of the complexity of the scene:

• A portion of one of the objects

• Two or more objects that may touch one another

• Two or more objects that may overlap one another

• One or more objects that may be defective

This list is ordered roughly by the increasing amount of effort

required to recognize and locate the object.

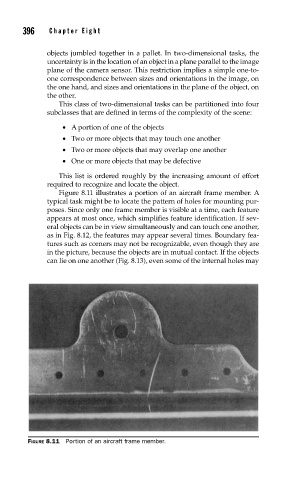

Figure 8.11 illustrates a portion of an aircraft frame member. A

typical task might be to locate the pattern of holes for mounting pur-

poses. Since only one frame member is visible at a time, each feature

appears at most once, which simplifies feature identification. If sev-

eral objects can be in view simultaneously and can touch one another,

as in Fig. 8.12, the features may appear several times. Boundary fea-

tures such as corners may not be recognizable, even though they are

in the picture, because the objects are in mutual contact. If the objects

can lie on one another (Fig. 8.13), even some of the internal holes may

FIGURE 8.11 Portion of an aircraft frame member.