Page 203 - Separation process engineering

P. 203

to 40.0°C. (i.e., it is subcooled).

b. Repeat part a except for a saturated liquid reflux. Compare with Part a.

D26. A distillation column with a partial condenser and a total reboiler is separating acetone and

ethanol. There are two feeds. One feed is 50.0 mol% acetone, flows at 100.0 mol/min, and is a

superheated vapor where approximately 1 mole of liquid will vaporize on the feed stage for each

20 moles of feed. The other feed is a saturated liquid, flows at 150.0 mol/min and is 35.0 mol%

acetone. We desire a distillate product that is y = 0.85 mole fraction acetone and a bottoms

D

product that is x = 0.10 mole fraction acetone. The column has a partial condenser and a total

B

reboiler. Boilup is returned as a saturated vapor. Column operates at a pressure of 1.0 atm.

Assume CMO and use a McCabe-Thiele diagram. VLE data are given in Problem 4.D7.

a. Find ( /B) . (Plot both feed lines to decide which one to use.)

min

b. Operate at /B = 3 × ( /B) . The partial condenser is an equilibrium contact. If the stages

min

each have a Murphree liquid efficiency of 0.75, find optimum feed locations for each feed and

total number of real stages. (It is easiest to start at top and step down.)

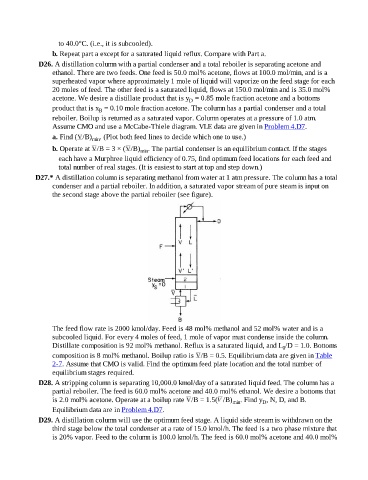

D27.* A distillation column is separating methanol from water at 1 atm pressure. The column has a total

condenser and a partial reboiler. In addition, a saturated vapor stream of pure steam is input on

the second stage above the partial reboiler (see figure).

The feed flow rate is 2000 kmol/day. Feed is 48 mol% methanol and 52 mol% water and is a

subcooled liquid. For every 4 moles of feed, 1 mole of vapor must condense inside the column.

Distillate composition is 92 mol% methanol. Reflux is a saturated liquid, and L /D = 1.0. Bottoms

0

composition is 8 mol% methanol. Boilup ratio is /B = 0.5. Equilibrium data are given in Table

2-7. Assume that CMO is valid. Find the optimum feed plate location and the total number of

equilibrium stages required.

D28. A stripping column is separating 10,000.0 kmol/day of a saturated liquid feed. The column has a

partial reboiler. The feed is 60.0 mol% acetone and 40.0 mol% ethanol. We desire a bottoms that

is 2.0 mol% acetone. Operate at a boilup rate /B = 1.5( /B) min . Find y , N, D, and B.

D

Equilibrium data are in Problem 4.D7.

D29. A distillation column will use the optimum feed stage. A liquid side stream is withdrawn on the

third stage below the total condenser at a rate of 15.0 kmol/h. The feed is a two phase mixture that

is 20% vapor. Feed to the column is 100.0 kmol/h. The feed is 60.0 mol% acetone and 40.0 mol%