Page 204 - Separation process engineering

P. 204

ethanol. We desire a distillate composition that is 90.0 mol% ethanol. We operate with an

external reflux ratio of L/D = 3. The bottoms product is 10.0 mol% acetone. A partial reboiler is

used. Find the mole fraction ethanol in the side stream x , the optimum feed location, and the total

s

number of equilibrium contacts needed. Equilibrium data are available in Problem 4.D7.

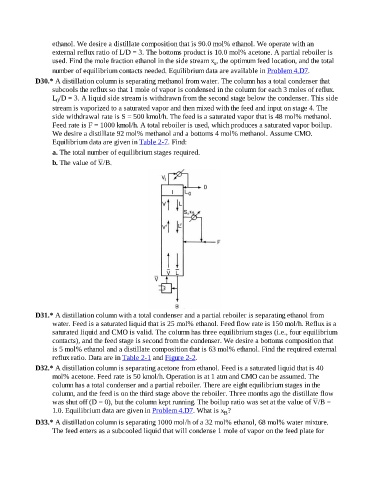

D30.* A distillation column is separating methanol from water. The column has a total condenser that

subcools the reflux so that 1 mole of vapor is condensed in the column for each 3 moles of reflux.

L /D = 3. A liquid side stream is withdrawn from the second stage below the condenser. This side

0

stream is vaporized to a saturated vapor and then mixed with the feed and input on stage 4. The

side withdrawal rate is S = 500 kmol/h. The feed is a saturated vapor that is 48 mol% methanol.

Feed rate is F = 1000 kmol/h. A total reboiler is used, which produces a saturated vapor boilup.

We desire a distillate 92 mol% methanol and a bottoms 4 mol% methanol. Assume CMO.

Equilibrium data are given in Table 2-7. Find:

a. The total number of equilibrium stages required.

b. The value of /B.

D31.* A distillation column with a total condenser and a partial reboiler is separating ethanol from

water. Feed is a saturated liquid that is 25 mol% ethanol. Feed flow rate is 150 mol/h. Reflux is a

saturated liquid and CMO is valid. The column has three equilibrium stages (i.e., four equilibrium

contacts), and the feed stage is second from the condenser. We desire a bottoms composition that

is 5 mol% ethanol and a distillate composition that is 63 mol% ethanol. Find the required external

reflux ratio. Data are in Table 2-1 and Figure 2-2.

D32.* A distillation column is separating acetone from ethanol. Feed is a saturated liquid that is 40

mol% acetone. Feed rate is 50 kmol/h. Operation is at 1 atm and CMO can be assumed. The

column has a total condenser and a partial reboiler. There are eight equilibrium stages in the

column, and the feed is on the third stage above the reboiler. Three months ago the distillate flow

was shut off (D = 0), but the column kept running. The boilup ratio was set at the value of /B =

1.0. Equilibrium data are given in Problem 4.D7. What is x ?

B

D33.* A distillation column is separating 1000 mol/h of a 32 mol% ethanol, 68 mol% water mixture.

The feed enters as a subcooled liquid that will condense 1 mole of vapor on the feed plate for