Page 268 - Separation process engineering

P. 268

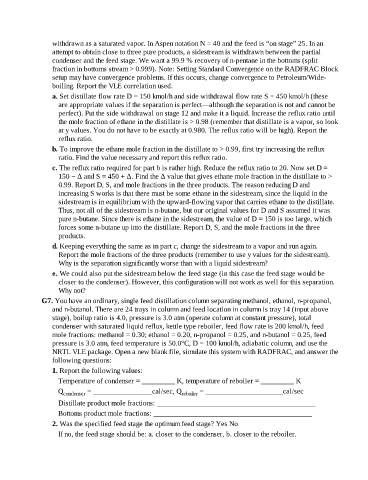

withdrawn as a saturated vapor. In Aspen notation N = 40 and the feed is “on stage” 25. In an

attempt to obtain close to three pure products, a sidestream is withdrawn between the partial

condenser and the feed stage. We want a 99.9 % recovery of n-pentane in the bottoms (split

fraction in bottoms stream > 0.999). Note: Setting Standard Convergence on the RADFRAC Block

setup may have convergence problems. If this occurs, change convergence to Petroleum/Wide-

boiling. Report the VLE correlation used.

a. Set distillate flow rate D = 150 kmol/h and side withdrawal flow rate S = 450 kmol/h (these

are appropriate values if the separation is perfect—although the separation is not and cannot be

perfect). Put the side withdrawal on stage 12 and make it a liquid. Increase the reflux ratio until

the mole fraction of ethane in the distillate is > 0.98 (remember that distillate is a vapor, so look

at y values. You do not have to be exactly at 0.980. The reflux ratio will be high). Report the

reflux ratio.

b. To improve the ethane mole fraction in the distillate to > 0.99, first try increasing the reflux

ratio. Find the value necessary and report this reflux ratio.

c. The reflux ratio required for part b is rather high. Reduce the reflux ratio to 20. Now set D =

150 − Δ and S = 450 + Δ. Find the Δ value that gives ethane mole fraction in the distillate to >

0.99. Report D, S, and mole fractions in the three products. The reason reducing D and

increasing S works is that there must be some ethane in the sidestream, since the liquid in the

sidestream is in equilibrium with the upward-flowing vapor that carries ethane to the distillate.

Thus, not all of the sidestream is n-butane, but our original values for D and S assumed it was

pure n-butane. Since there is ethane in the sidestream, the value of D = 150 is too large, which

forces some n-butane up into the distillate. Report D, S, and the mole fractions in the three

products.

d. Keeping everything the same as in part c, change the sidestream to a vapor and run again.

Report the mole fractions of the three products (remember to use y values for the sidestream).

Why is the separation significantly worse than with a liquid sidestream?

e. We could also put the sidestream below the feed stage (in this case the feed stage would be

closer to the condenser). However, this configuration will not work as well for this separation.

Why not?

G7. You have an ordinary, single feed distillation column separating methanol, ethanol, n-propanol,

and n-butanol. There are 24 trays in column and feed location in column is tray 14 (input above

stage), boilup ratio is 4.0, pressure is 3.0 atm (operate column at constant pressure), total

condenser with saturated liquid reflux, kettle type reboiler, feed flow rate is 200 kmol/h, feed

mole fractions: methanol = 0.30; ethanol = 0.20, n-propanol = 0.25, and n-butanol = 0.25, feed

pressure is 3.0 atm, feed temperature is 50.0°C, D = 100 kmol/h, adiabatic column, and use the

NRTL VLE package. Open a new blank file, simulate this system with RADFRAC, and answer the

following questions:

1. Report the following values:

Temperature of condenser = _________ K, temperature of reboiler = _________ K

Q condenser = ________________cal/sec, Q reboiler = _____________________cal/sec

Distillate product mole fractions: ___________________________________________

Bottoms product mole fractions: ___________________________________________

2. Was the specified feed stage the optimum feed stage? Yes No

If no, the feed stage should be: a. closer to the condenser, b. closer to the reboiler.