Page 251 - Separation process principles 2

P. 251

216 Chapter 6 Absorption and Stripping of Dilute Mixtures

Vapor

drag

( 1

Fb = pV p g, buoyancy /

Liquid I

droplet:

density, p,

diameter, 4

IFg = pL (%).#

gravity

Vapor:

density, pv

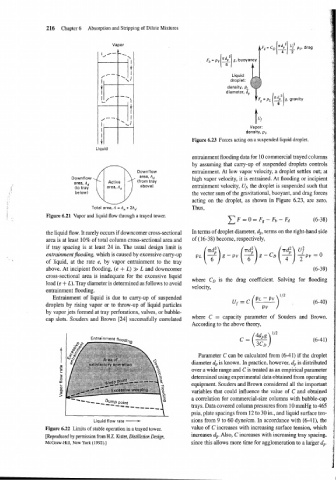

Figure 6.23 Forces acting on a suspended liquid droplet.

Liquid

entrainment flooding data for 10 commercial trayed columns

by assuming that carry-up of suspended droplets controls

0

area, Ad

Downflow Downflow entrainment. At low vapor velocity, a droplet settles out; at

high vapor velocity, it is entrained. At flooding or incipient

area, Ad Active (from tray

(to tray area, A, above) entrainment velocity, Uf, the droplet is suspended such that

below) the vector sum of the gravitational, buoyant, and drag forces

Thus,

Total area, A =A, + 2Ad acting on the droplet, as shown in Figure 6.23, are zero.

Figure 6.21 Vapor and liquid flow through a trayed tower.

the liquid flow. It rarely occurs if downcomer cross-sectional In terms of droplet diameter, dp, terms on the right-hand side

area is at least 10% of total column cross-sectional area and of (16-38) become, res~eclivel~,

if tray spacing is at least 24 in. The usual design limit is

entrainmentJooding, which is caused by excessive carry-up

of liquid, at the rate e, by vapor entrainment to the tray

above. At incipient flooding, (e + L) >> L and downcomer (6-39)

cross-sectional area is inadequate for the excessive liquid

where CD is the drag coefficient. Solving for flooding

load (e + L). Tray diameter is determined as follows to avoid

velocity,

entrainment flooding.

"

Entrainment of liquid is due to carry-up of suspended

droplets by rising vapor or to throw-up of liquid particles

by vapor jets formed at tray perforations, valves, or bubble-

cap slots. Souders and Brown [24] successfully correlated where = capacity parameter of and Brown.

According to the above theory,

Parameter C can be calculated from (6-41) if the droplet

diameter dp is known. In practice, however, dp is distributed

over a wide range and C is treated as an empirical parameter

determined using experimental data obtained from operating

equipment. Souders and Brown considered all the important

variables that could influence the value of C and obtained

a correlation for commercial-size columns with bubble-cap

trays. Data covered column pressures from 10 mmHg to 465

Liquid flow rate - psia, plate spacings from 12 to 30 in., and liquid surface ten-

sions from 9 to 60 dynelcm. In accordance with (6-41), the

Figure 6.22 Limits of stable operation in a trayed tower. value of C increases with increasing surface tension, which

[Reproduced by permission from H.Z. Kister, Distillation Design, increases dp. Also, C increases with increasing tray spacing,

McGraw-Hill, New York (1992).] since this allows more time for agglomeration to a larger dp.