Page 103 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 103

CH07pp068-82 4/10/02 12:50 PM Page 81

Understanding the Risks 81

Mishap Risk Categories

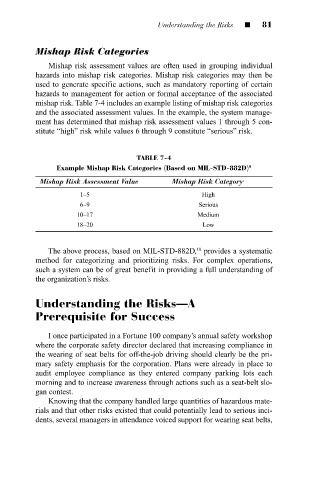

Mishap risk assessment values are often used in grouping individual

hazards into mishap risk categories. Mishap risk categories may then be

used to generate specific actions, such as mandatory reporting of certain

hazards to management for action or formal acceptance of the associated

mishap risk. Table 7-4 includes an example listing of mishap risk categories

and the associated assessment values. In the example, the system manage-

ment has determined that mishap risk assessment values 1 through 5 con-

stitute “high” risk while values 6 through 9 constitute “serious” risk.

TABLE 7-4

Example Mishap Risk Categories (Based on MIL-STD-882D) 9

Mishap Risk Assessment Value Mishap Risk Category

1–5 High

6–9 Serious

10–17 Medium

18–20 Low

10

The above process, based on MIL-STD-882D, provides a systematic

method for categorizing and prioritizing risks. For complex operations,

such a system can be of great benefit in providing a full understanding of

the organization’s risks.

Understanding the Risks—A

Prerequisite for Success

I once participated in a Fortune 100 company’s annual safety workshop

where the corporate safety director declared that increasing compliance in

the wearing of seat belts for off-the-job driving should clearly be the pri-

mary safety emphasis for the corporation. Plans were already in place to

audit employee compliance as they entered company parking lots each

morning and to increase awareness through actions such as a seat-belt slo-

gan contest.

Knowing that the company handled large quantities of hazardous mate-

rials and that other risks existed that could potentially lead to serious inci-

dents, several managers in attendance voiced support for wearing seat belts,