Page 102 - Shale Shakers Drilling Fluid Systems

P. 102

HISTORICAL PERSPECTIVE 85

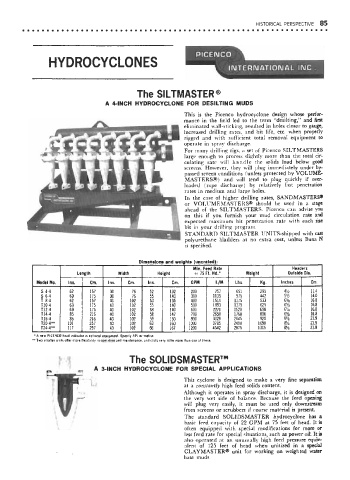

HYDROCYCLONES

The SILTMASTER®

A 4-INCH HYDROCYCLONE FOR DESILTING MUDS

This Is the Picenco hydrocyclone design whose perfor-

mance in the field led to the term "desilting," and first

eliminated wall-sticking, resulted in holes closer to gauge,

increased drilling rates, and bit life, etc. when properly

rigged and with sufficient total removal equipment to

operate in spray discharge.

For many drilling rigs, a set of Picenco SILTMASTERS

large enough to process slightly more than the total cir-

culating rate will handle the solids load below good

screens. However, they will plug immediately under by-

passed screen conditions (unless protected by VOLUME-

MASTERS®) and will tend to plug quickly if over-

loaded (rope discharge) by relatively fast penetration

rates in medium and large holes.

In the case of higher drilling rates, BANDMASTERS®

or VOLUMEMASTERS* should be used in a stage

ahead of the SILTMASTERS. Picenco can advise you

on this if you furnish your mud circulation rate and

expected maximum bit penetration rate with each size

bit in your drilling program,

STANDARD SILTMASTER UNITS-shipped with cast

polyurethane bladders at no extra cost, unless Buna N

is specified.

Dimensions and weights (uncrated):

Win. Feed Rate Headers

Length Width Height @ 75 Ft, Hd.* Weight Outside Dia.

Model No. Ins. Cm. Ins. Cm. Ins, Cm. GPSJ L/M Lbs. Kg. Inches Cm.

S 4-4 62 157 30 76 52 132 200 757 651 295 4»/i 11,4

S 6-4 69 175 30 76 55 140 300 1135 975 442 514 14.0

T 8-4 62 157 40 102 53 135 400 1514 1175 533 6% 16.8

T10-4 69 175 40 102 55 140 500 1893 1375 625 6% 16.8

T12-4 69 175 40 102 58 140 600 2271 1520 690 6H 16.8

T14-4 85 216 40 102 58 147 700 2650 1760 800 6% 16J

TIM 85 216 40 102 59 150 800 3028 2045 928 8H 21.9

T20-4** 101 257 40 102 63 160 1000 3785 2400 1090 8ft 21.9

T24-4** 117 297 40 102 66 167 1200 4542 2875 1305 8% 21.9

* A new PICENCO head indicator is optional equipment Sptcity API or metric,

1

Two smaller units offer more flexibility in operation and maintenance, and costs very little more than one of these.

The SOLIDSMASTER™

A 3-INCH HYDROCYCLONE FOR SPECIAL APPLICATIONS

This cyclone is designed to make a very fine separation

at a constantly high feed solids content.

Although it operates in spray discharge, it is designed on

the very wet side of balance. Because the feed opening

will plug very easily., it must be used only downstream

from screens or scrubbers if coarse material is present.

The standard SOLIDSMASTER hydrocyclone has a

basic feed capacity of 22 GPM at 75 feet of head. It is

often equipped with special modifications for more or

less feed rate for special situations, such as power oil It is

also operated at an unusually high feed pressure equiv-

alent of 125 feet of head when unitized in a special

CLAYMASTER* unit for working on weighted water

base muds.