Page 103 - Shale Shakers Drilling Fluid Systems

P. 103

86 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

SWECO, Inc., Dept. 215-542, 6033 E. Bandini Blvd., P.O. Box 4151,

Los Angeles, CA 90051, (213) 726-1177, Telex: 67-4968

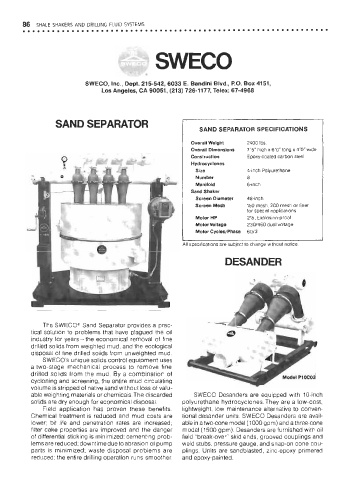

SAND SEPARATOR

SAND SEPARATOR SPECIFICATIONS

Overall Weight 2400 Ibs.

Overall Dimensions 7'5" high x 6'0" long x 4'0" wide

Construction Epoxy-coated carbon steel

Hydrocyclones

Size 4-inch Polyurethane

Number 8

Manifold 6-inch

Sand Shaker

Screen Diameter 48-inch

Screen Mesh 150 mesh, 200 mesh or finer

for special applications

1

Motor HP 2 /2, Explosion-proof

Motor Voltage 230/460 dual voltage

Motor Cycles/Phase 60/3

All specifications are subject to change without notice.

The SWECO® Sand Separator provides a prac-

tical solution to problems that have plagued the oil

industry for years-the economical removal of fine

drilled solids from weighted mud, and the ecological

disposal of fine drilled solids from unweighted mud.

SWECO's unique solids control equipment uses

a two-stage mechanical process to remove fine

drilled solids from the mud. By a combination of

cycloning and screening, the entire mud circulating

volume is stripped of native sand without loss of valu-

able weighting materials or chemicals. The discarded SWECO Desanders are equipped with 10-inch

solids are dry enough for economical disposal. polyurethane hydrocyclones.They are a low-cost,

Field application has proven these benefits: lightweight, low maintenance alternative to conven-

Chemical treatment is reduced and mud costs are tional desander units. SWECO Desanders are avail-

lower; bit life and penetration rates are increased; able in a two-cone model (1000 gpm) and a three-cone

filter cake properties are improved and the danger model (1500 gpm). Desanders are furnished with oil

of differential sticking is minimized; cementing prob- field "break-over" skid ends, grooved couplings and

lems are reduced; downtime due to abrasion of pump weld stubs, pressure gauge, and snap-on cone cou-

parts is minimized; waste disposal problems are plings. Units are sandblasted, zinc-epoxy primered

reduced; the entire drilling operation runs smoother. and epoxy-painted.