Page 221 - Shale Shakers Drilling Fluid Systems

P. 221

ELECTRIC MOTORS 203

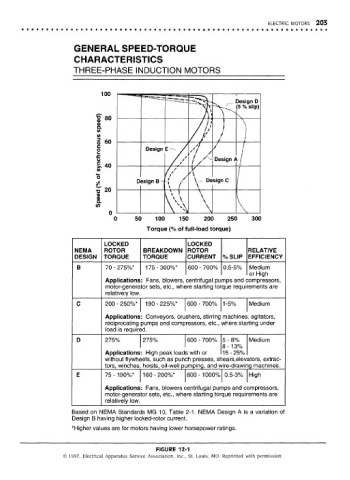

GENERAL SPEED-TORQUE

CHARACTERISTICS

THREE-PHASE INDUCTION MOTORS

LOCKED LOCKED

NEMA ROTOR BREAKDOWN ROTOR RELATIVE

DESIGN TORQUE TORQUE CURRENT % SLIP EFFICIENCY

B 70 - 275%* 175-300%* 600 - 700% 0.5-5% Medium

or High

Applications: Fans, blowers, centrifugal pumps and ccompressors,

motor-generator sets, etc., whe jre starting torque requirements are

relatively low.

C 200 - 250%* 190-225%* 600 - 700% 1-5% Medium

Applications: Conveyors, crushers, stirring machines , agitators,

reciprocating pumps and compressors, etc., where starting under

load is require3d.

D 275% 275% 600 - 700% 5 - 8% Medium

8 - 1 3%

Applications: High peak loads with or 15-25%

without flywh€jels, such as punDh presses, sriears,elevators, extrac-

tors, winches hoists, oil-well pijmping, and w/ire-drawirig machines.

E 75-190%* 160-200%* 1 800 -1000% 0.5-3% High

Applications: Fans, blowers centrifugal purnps and compressors,

motor-generator sets, etc., where starting tor que requirements are

relatively low.

Based on NEMA Standards MG 10, Table 2-1. NEMA Design A is a variation of

Design B having higher locked-rotor current.

*Higher values are for motors having lower horsepower ratings.

FIGURE 12-1

© 1997, Electrical Apparatus Service Association, Inc., St. Louis, MO. Reprinted with permission.